- Overview

- Related Products

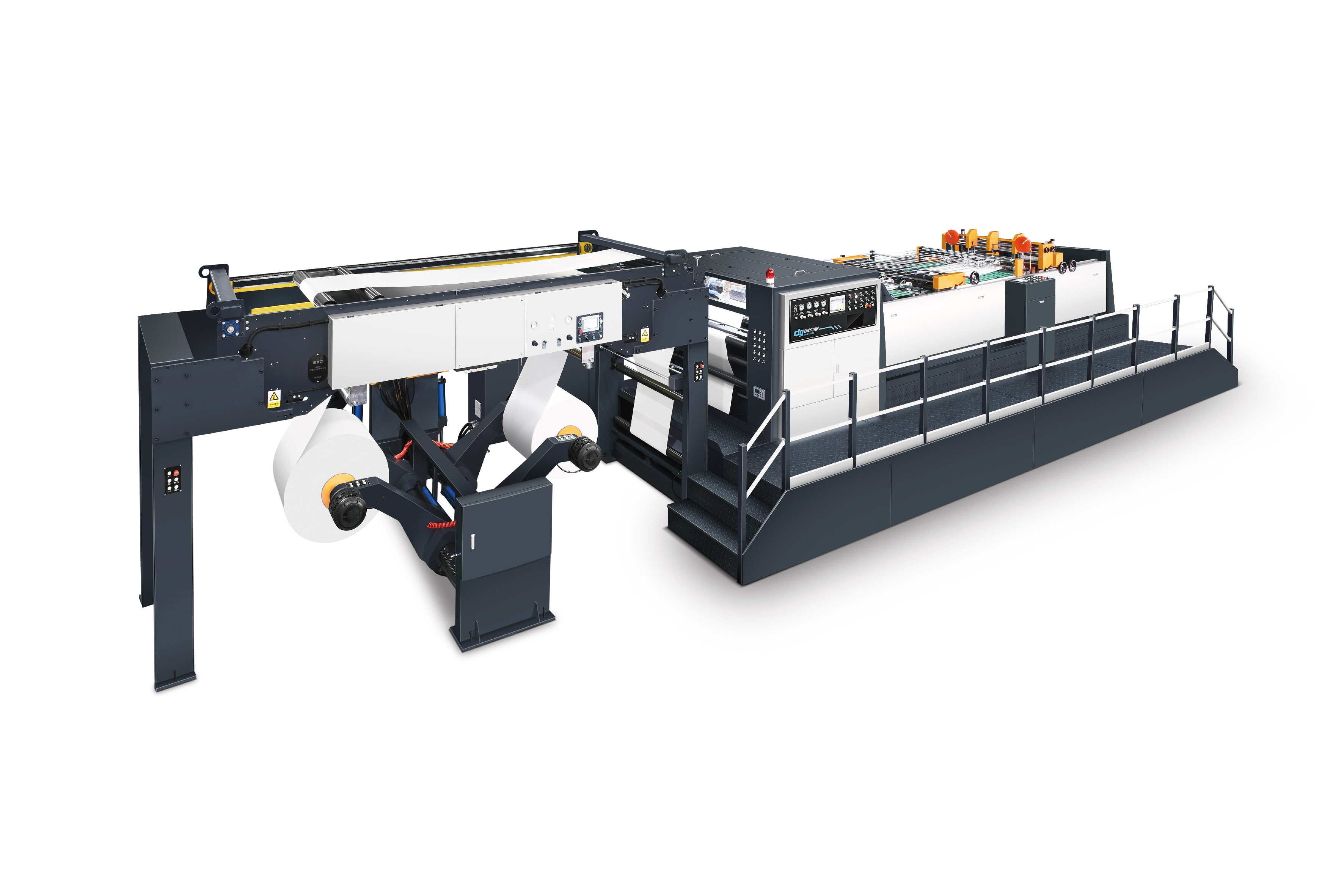

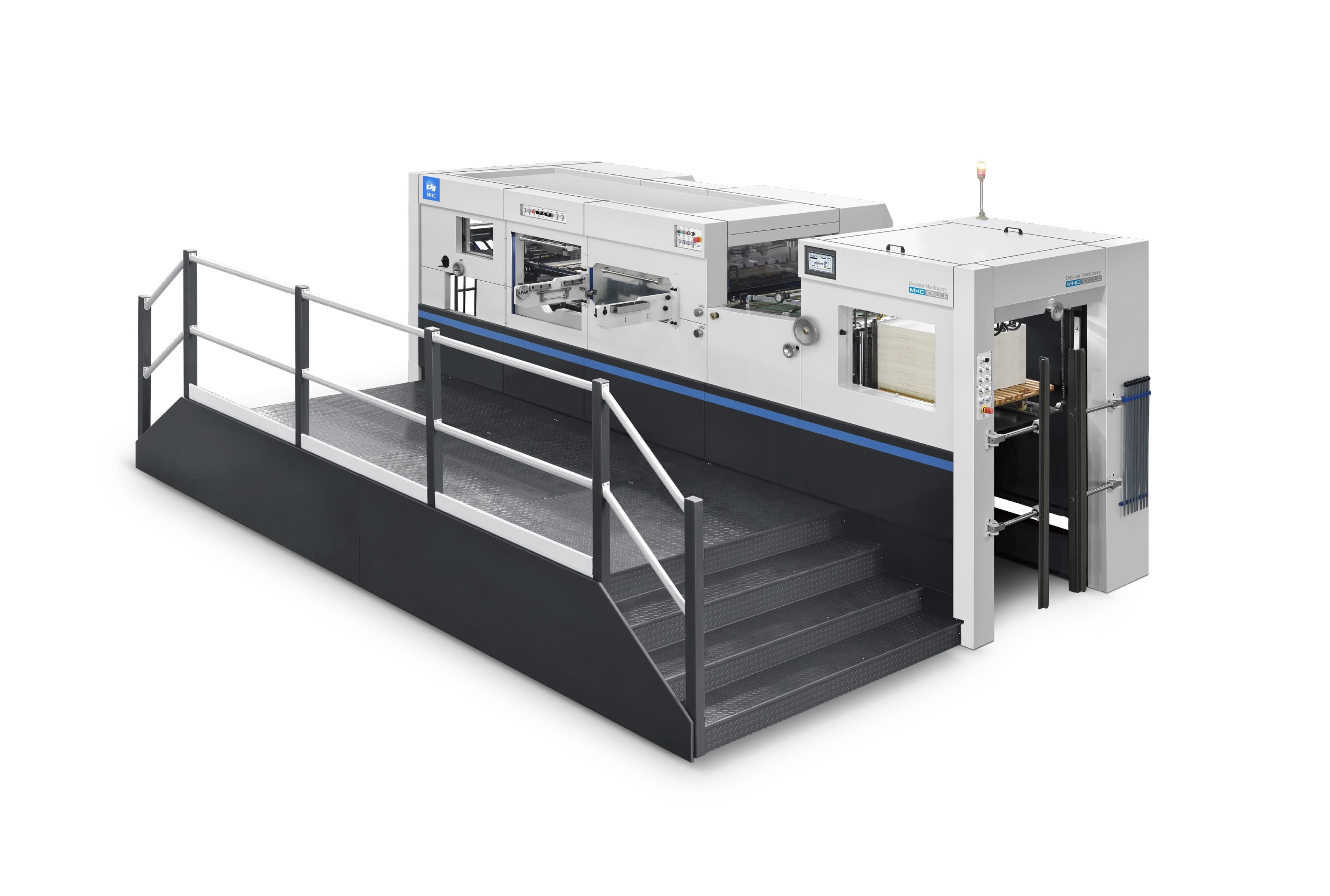

The CM - 1100/1400/1700/1900A Servo Precision High Speed Sheet Cutter, which is controlled by a computer, features simple operation, stable paper - cutting speed, and high cutting accuracy. It is a commonly - used product processing machine in the current paper - making and printing industries.

|

|

|

1: Paper rack stand |

2: Automatic anti - curve equipment |

3: Automatic stacker |

|

|

|

|

4: Paper feeding unit |

5: Electric appliance unit |

6: Overlapping unit Single sheet outlet can be adjusted by the overlapping unit |

Model |

CM-1100/1500/1700/1900 |

Model of cutting paper |

|

Thickness of cutting paper |

60-550gsm |

Cutting length range |

450-1650mm |

Cutting precision |

Cutting length≤1000mm:±0.5mm Cutting length>1000mm:±0.1% |

Max. cutting meter speed |

300m/min |

Max. cutting speed |

400cuts/min |

Max. scroll diameter |

1800mm |

Max. paper cutting width |

1100(45”)mm 1500(59” )mm 1700(67” )mm 1900(75”)mm |

Max. paper piling height |

1500mm |

The request for air compressor |

0.8Mpa |

Power consumption |

380V/220V×50HZ |

G.W. |

9000kgs/11000kgs/13000kgs/15000kgs |

Full-load Power |

22/26/30/35kw |

FAQ:

Q: What is the delivery time for CM-A Series?

A: The delivery time is approximately 30 days. The specific time depends on the degree of customization of the project.

Q: Can your machines be used in areas with extreme weather conditions?

A: Generally speaking, they can be used. However, it needs to be analyzed according to the specific environment. You can send an inquiry to consult us.

Q: Are there any color options for the machine?

A: You can customize special color schemes! The color scheme of our equipment is usually as shown in the diagram, and you can customize it according to your preferences.

Q: How to maintain and clean the die - cutting machine?

A: Under the guidance of professionals, regularly clean the machine body and components. Do a good job in lubrication and electrical inspections, calibrate the accuracy, replace vulnerable parts as needed, and maintain the production environment.

Q: Does the machine have safety production measures?

A: Yes, it does. We will train your workers. Meanwhile, safety doors, photoelectric sensors and other facilities are installed on the machine. Warning signs are posted in prominent positions to ensure production is carried out safely and in compliance with regulations. You can also add more safety - production facilities based on what we've provided.

Q: Do you provide installation services? And do you have a warranty period?

A: Certainly. We offer free first - time installation training and provide free spare parts within the one - year warranty period. For services beyond the warranty period, we will charge a reasonable fee.

Are you ready to enhance the efficiency of your production with our printing and packaging solutions? Contact Us today to get a free consultation and quote. Our team of experts is always ready to assist you.

E-mail adress:[email protected]

TEL:+86-13758835289

Manufacture the best equipment to create value for customers.