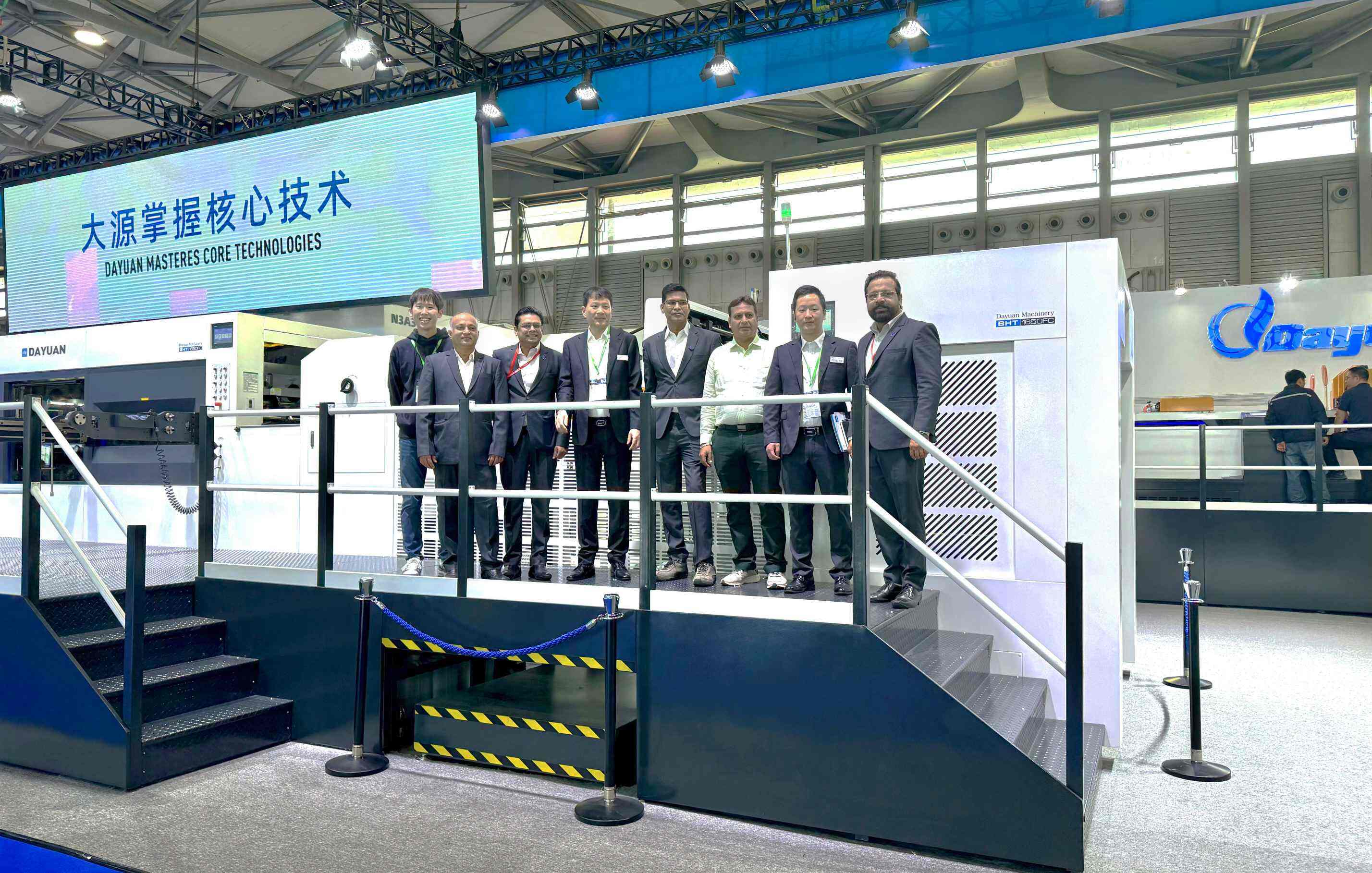

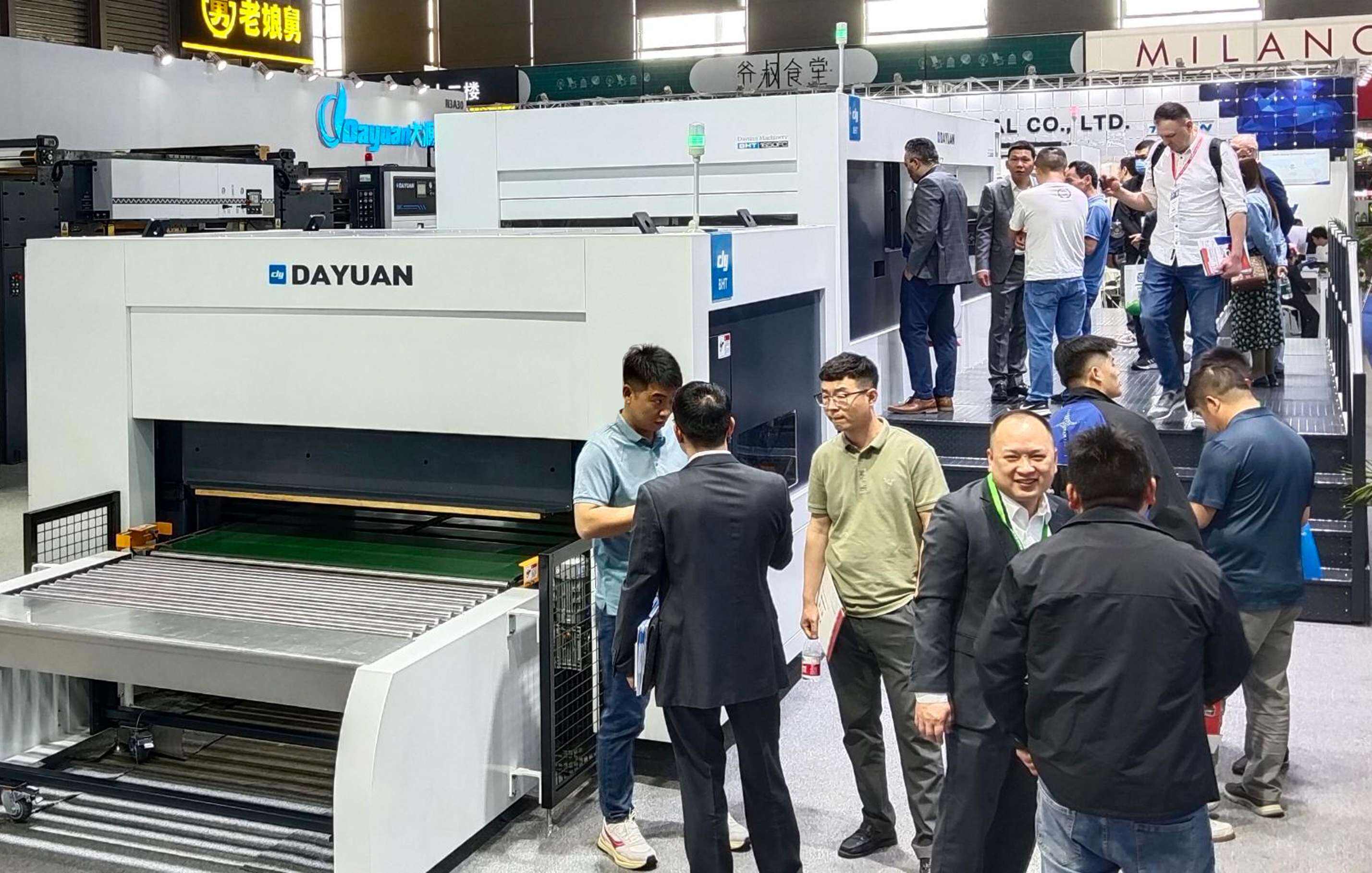

The three-day WEPACK 2025 concluded successfully! Dayuan made a stunning appearance with four flagship models, becoming the spotlight of the exhibition with its intelligent and high-efficiency solutions. The venue was bustling with crowds, as clients from around the world stopped by for in-depth technical discussions. Numerous domestic and international companies placed on-site orders.

BHT-1650FC Automatic Die Cutting Machine Linkage Production Line was the star product of this exhibition. Linkage Production Line can be customized to meet different customer requirements and product processes, supporting personalized configurations and the integration of upstream and downstream production lines. Compared to traditional standalone machines, the integrated line significantly boosts production capacity and reduces paper waste, directly addressing pain points such as slow mass production and inefficient material consumption.

It is compatible with corrugated paper ≤8.5mm thick, including E, B, C, A, and AB flute types, meeting export-grade packaging strength requirements for multi-panel beer cartons and similar products.

The flexible combination of a push-type automatic paper feeder + die-cutting unit + stripping unit + multi-functional automatic sheet breaker integrates multiple standalone machines into a comprehensive, seamlessly connected production line, eliminating unnecessary material handling.

The accompanying paper breaker provides an intelligent solution for sorting multi-panel stacks and post-die-cutting processing. It achieves both vertical and horizontal separation in a single pass, eliminating the need for reorientation and delivering flexible, high-efficiency performance to meet customized production demands.

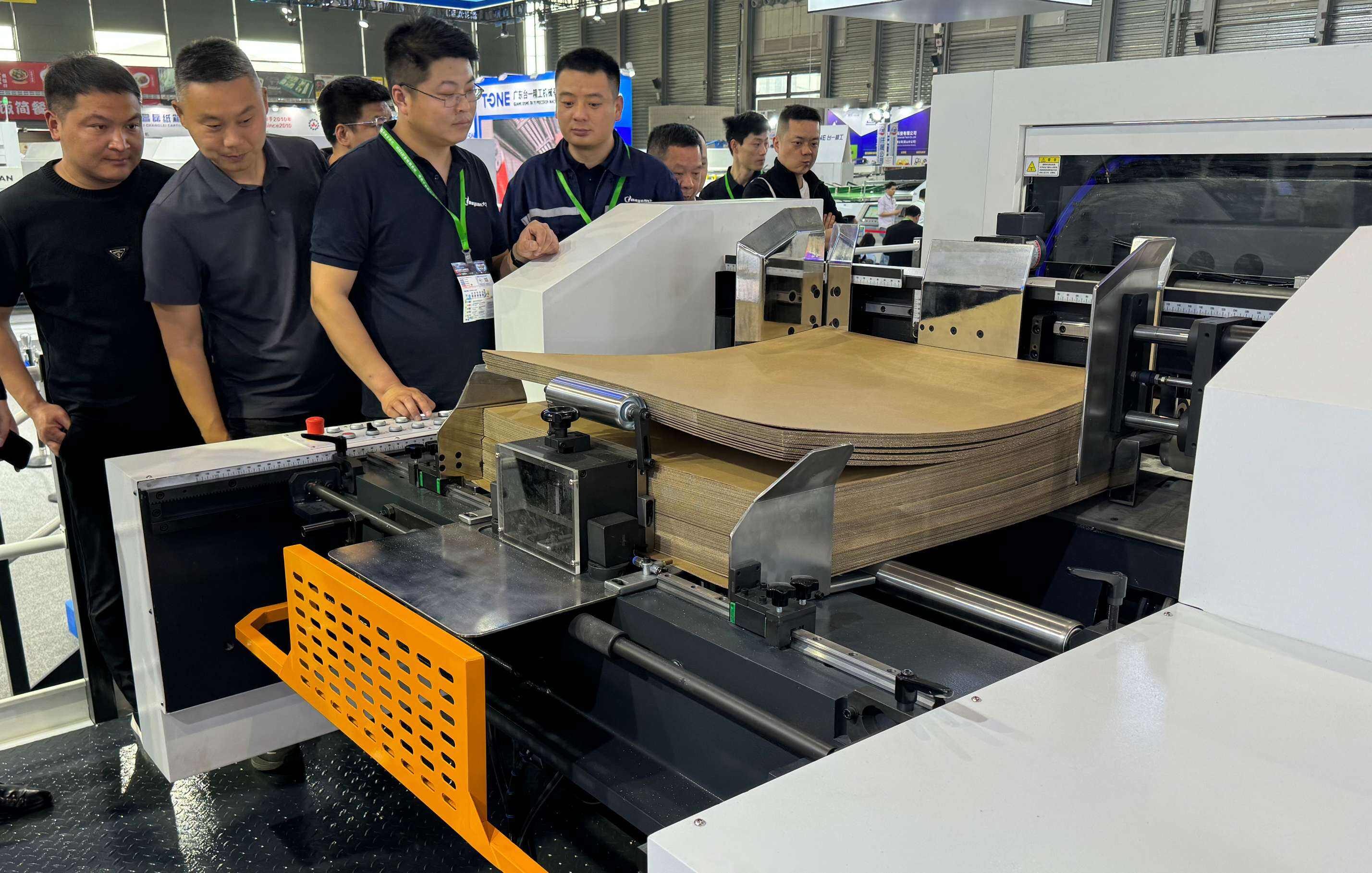

SMC-1500ZH Servo Precision Double Helix High Speed Sheet Cutter – Our Flagship Equipment at This Exhibition

With one-key startup, SMC-1500ZH achieves fully automated centralized alignment, delivering seamless operation with non-stop paper splicing, automatic curl correction, edge adjustment, longitudinal cutting, slitting, stacking, and tray switching—all at a maximum speed of 540 cuts per minute.

Featuring vacuum suction transport, it ensures scratch-free and dent-free paper surfaces, guaranteeing premium product quality. This system is designed to meet the demands of high-volume production, maximizing efficiency while maintaining precision.

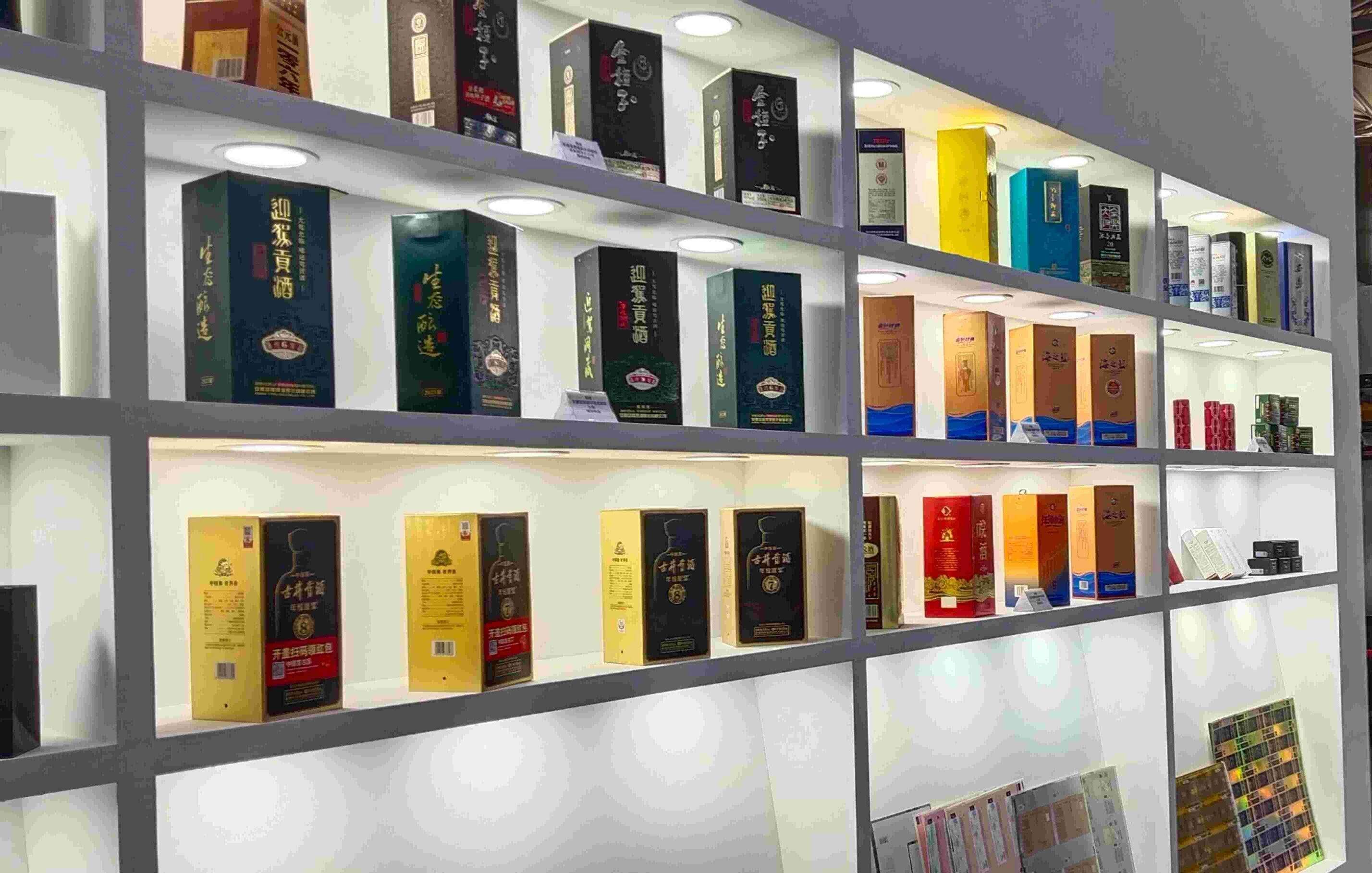

The MHK-1180EFC Automatic Die Cutting & Creasing Machine with Stripping (Down Feeder) is a brand-new equipment launched by Dayuan this year for the milk packaging market in combination with market research. The maximum paper format is 1180x1050mm. The equipment adopts the industry-leading paper feeding technology with a down feeder, which significantly reduces the requirements for paper flatness. At the same time, it ensures zero damage to the paper surface and is perfectly suitable for E, B, C, A and AB corrugated papers with a thickness of ≤8.5mm.

In addition, the exhibited BHT-1060CE Automatic Die Cutting & Creasing Machine with Stripping is specifically designed to meet the needs of high-efficiency die cutting and waste removal, with a maximum speed of up to 9,000 sheets per hour.

It is equipped with a feeder featuring four suction and six feeding functions and an ultrasonic double-sheet detection device, which effectively avoids problems such as double sheets and paper jams. The die cutting section applies the turbine variable speed transmission technology, enabling the moving platform to operate precisely at variable speeds, effectively reducing the defects of continuous dots and improving the die cutting quality. It is equipped with a quick fine-tuning plate frame and a fine-tuning cutting plate, directly reducing the plate adjustment time by 50%. The gripper bar is made of flexible and durable carbon fiber material with small gripper nozzles.

The stripping section is equipped with a waste removal system with three frames and four sides. The upper and lower frames operate while the middle frame remains stationary to prevent the phenomenon of loose plates. The paper receiving section adopts the design of a non-stop curtain secondary paper receiving device, enabling continuous paper receiving without stopping the machine.

Dayuan focuses deeply on the research and development of core technologies. Relying on world-leading hot stamping, die cutting and paper cutting equipment, it has occupied a leading position in the packaging equipment manufacturing industry. We sincerely hope that users can witness our excellent performance at the 2025 WEPACK World Packaging Industry Expo, and let the world get to know "DAYUAN".

In the future, Dayuan will continue to deeply cultivate intelligent manufacturing, create value for customers, and embark on a new journey together with the industry. Dayuan looks forward to jointly writing a new chapter in the printing and packaging industry with global partners and helping the industry achieve intelligent transformation and upgrading.

Hot News

Hot News2025-04-23

2025-04-02

2024-06-25

2021-11-16

2020-10-25

2020-10-21