- ภาพรวม

- สินค้าที่เกี่ยวข้อง

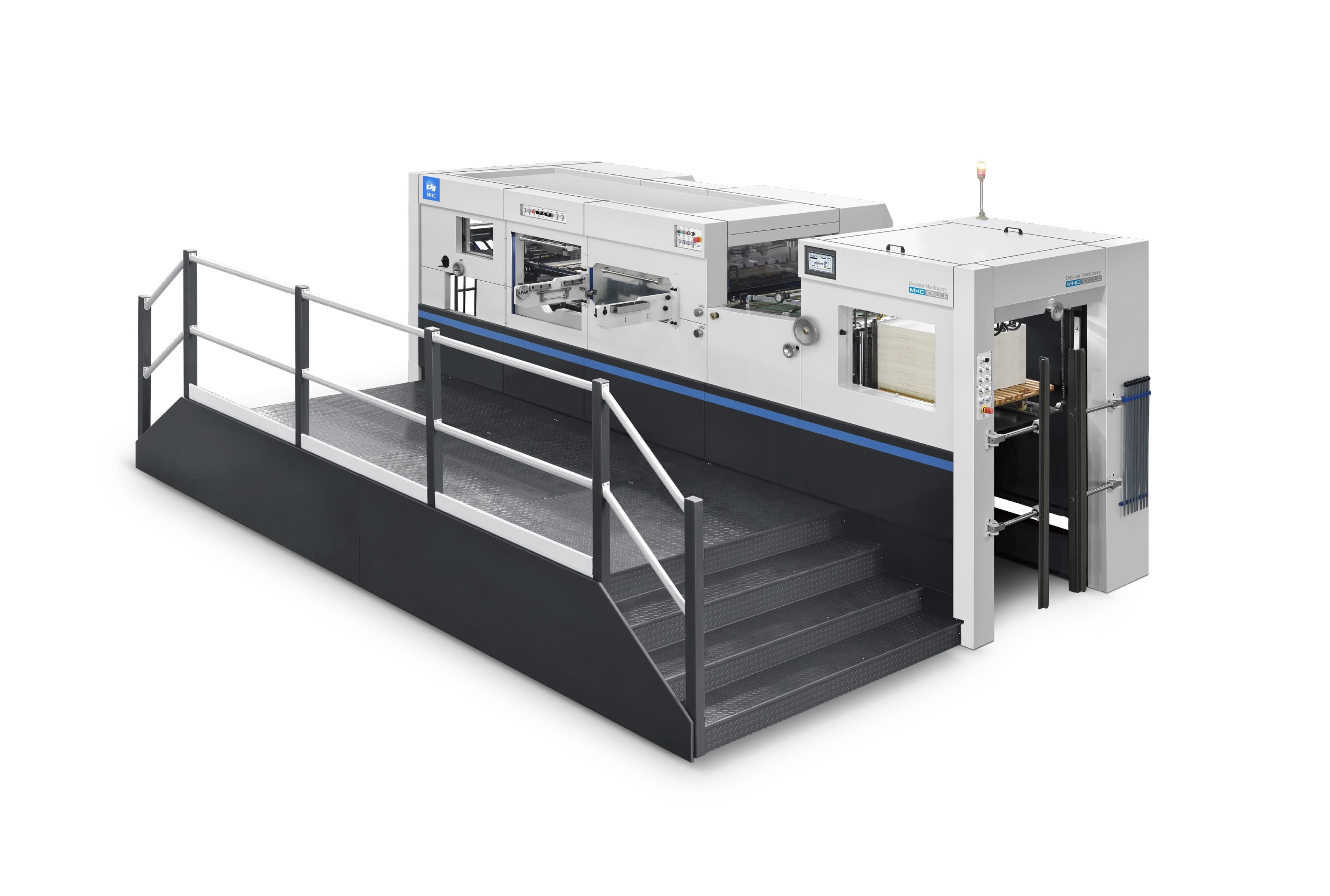

เครื่องตัดและพับอัตโนมัติแบบสตริปปิ้ง MHC - 1060CE ที่คลาสสิกและทันสมัย เครื่องตัดนี้ใช้โหมดการผลิตอัตโนมัติเต็มรูปแบบ เมื่อเปรียบเทียบกับโหมดการผลิตกึ่งอัตโนมัติ จะทำให้การผลิตง่ายขึ้น การกำจัดเศษอย่างรวดเร็วและการตัดแบบแม่นยำ รวมถึงคุณภาพผลิตภัณฑ์สำเร็จรูปที่มีเสถียรภาพ

|

|

|

|

1: เครื่องป้อน หัวเครื่องป้อนกระดาษความเร็วสูงสามารถปรับได้ตามสภาพกระดาษ |

2: หน่วยการขนส่ง ใช้พลังงานเสริมจากสปริงก๊าซและกลไกการลดความเร็วสำหรับการทำงานในที่ และติดตั้งอุปกรณ์ปรับล้อกดกระดาษแบบรวม ซึ่งทำให้การปรับสะดวกและรวดเร็ว |

3: อุปกรณ์ขับเคลื่อนด้วยสายพาน การแบ่งส่วนแบบไม่ต่อเนื่องที่มีความแม่นยำสูงจากไต้หวันรับประกันความแม่นยำในการวางตำแหน่งสูงสำหรับการใช้งานระยะยาว |

|

|

|

|

4: ส่วนการกำจัดของเสีย(สามกรอบ) แผ่นกำจัดของเสียระดับกลางติดตั้งโดยใช้วิธีการจัดตำแหน่งศูนย์กลางอย่างรวดเร็ว ซึ่งช่วยให้ผู้ปฏิบัติงานติดตั้งแผ่นกำจัดของเสียได้อย่างรวดเร็วและเพิ่มประสิทธิภาพในการเปลี่ยนแผ่น |

5: ส่วนการเก็บกระดาษรองที่ไม่หยุดหมุน อุปกรณ์เก็บหลักและสวิตช์อุปกรณ์เก็บอัตโนมัติที่ไม่หยุดทำงานโดยอัตโนมัติโดยไม่ต้องมีการดำเนินการใด ๆ ซึ่งทำให้เครื่องมีประสิทธิภาพมากขึ้น |

6: การหล่อลื่นแบบเข้มข้น เครื่องทั้งหมดติดตั้งระบบจ่ายน้ำมันอัตโนมัติแบบรวมศูนย์เพื่อให้แน่ใจว่าส่วนประกอบการส่งผ่านไม่มีน้ำมันขาดแคลน |

รุ่น |

เอ็มเอชซี-1060ซีอี |

ขนาดแผ่นสูงสุด,มม |

1060×760 |

ขนาดแผ่นขั้นต่ำ,มม |

400×350 |

ขนาดช่องภายใน,มม |

1120×786 |

ขนาดตัดสูงสุด,มม |

1050×750 |

ความกว้างขั้นต่ำของการตัดคู่,มม |

10-18 |

ขอบที่จับขั้นต่ำ,มม |

9-17 |

ความสูงของกฎการตัด,มม |

23.8 |

ช่วงสต็อก,มม |

80~2000g/m²,0.1~2mm,≤4mm กระดาษ: จาก 80 ถึง 2000g/m2, 0.1~2mm, กระดาษลูกฟูก: สูงสุด 4mm |

ความแม่นยำในการตัดแม่พิมพ์,มม |

≤±0.1 |

แรงตัดสูงสุด,T |

300ตัน |

ความเร็วในการทำงานสูงสุด,s/h |

7500 |

น้ำหนักสุทธิของเครื่อง,T |

17 |

ความสูงของกองสูงสุดที่เครื่องป้อน-โหมดปกติ,มม |

1600 |

ความสูงของกองสูงสุดที่การจัดส่ง,มม |

1400 |

กำลังโหลดเต็ม,KW |

18 |

ความต้องการอากาศ |

0.6~0.7MPa,≥0.37m3/min |

คำถามที่พบบ่อย :

ถาม: เวลาจัดส่งสำหรับ MHC-1060CE คืออะไร?

ตอบ: เวลาจัดส่งประมาณ 30 วัน เวลาที่แน่นอนขึ้นอยู่กับระดับการปรับแต่งของโครงการ.

Q: เครื่องของคุณสามารถใช้ในพื้นที่ที่มีสภาพอากาศสุดขั้วได้หรือไม่?

A: โดยทั่วไปแล้วสามารถใช้ได้ อย่างไรก็ตาม ต้องวิเคราะห์ตามสภาพแวดล้อมเฉพาะ คุณสามารถส่งคำถามเพื่อปรึกษาเรา

Q: มีตัวเลือกสีสำหรับเครื่องหรือไม่?

A: คุณสามารถปรับแต่งสีพิเศษได้! แผนผังสีของอุปกรณ์ของเรามักจะแสดงตามในแผนภาพ และคุณสามารถปรับแต่งตามความชอบของคุณ

Q: วิธีการบำรุงรักษาและทำความสะอาดเครื่องตัด?

A: ภายใต้การแนะนำของผู้เชี่ยวชาญ ให้ทำความสะอาดตัวเครื่องและส่วนประกอบเป็นประจำ ทำการหล่อลื่นและตรวจสอบไฟฟ้าให้ดี ปรับเทียบความแม่นยำ เปลี่ยนชิ้นส่วนที่สึกหรอตามความจำเป็น และรักษาสภาพแวดล้อมการผลิต

Q: เครื่องมีมาตรการความปลอดภัยในการผลิตหรือไม่?

A: ใช่ มันทำ เราจะฝึกอบรมคนงานของคุณ ในระหว่างนี้ ประตูนิรภัย เซ็นเซอร์โฟโต้อิเล็กทริก และสิ่งอำนวยความสะดวกอื่น ๆ ถูกติดตั้งบนเครื่อง เครื่องหมายเตือนภัยถูกติดตั้งในตำแหน่งที่เด่นชัดเพื่อให้แน่ใจว่าการผลิตดำเนินการอย่างปลอดภัยและเป็นไปตามกฎระเบียบ คุณยังสามารถเพิ่มสิ่งอำนวยความสะดวกด้านความปลอดภัย - การผลิตเพิ่มเติมตามสิ่งที่เรามีให้

Q: คุณมีบริการติดตั้งหรือไม่? และคุณมีระยะเวลาการรับประกันหรือไม่?

A: แน่นอน เรามีการฝึกอบรมการติดตั้งครั้งแรกฟรีและให้ชิ้นส่วนสำรองฟรีภายในระยะเวลาการรับประกันหนึ่งปี สำหรับบริการที่เกินระยะเวลาการรับประกัน เราจะเรียกเก็บค่าธรรมเนียมที่เหมาะสม

คุณพร้อมที่จะเพิ่มประสิทธิภาพการผลิตของคุณด้วยโซลูชันการพิมพ์และบรรจุภัณฑ์ของเราแล้วหรือยัง?ติดต่อเราวันนี้เพื่อขอคำปรึกษาฟรีและเสนอราคา ทีมผู้เชี่ยวชาญของเราพร้อมที่จะช่วยเหลือคุณเสมอ

ที่อยู่อีเมล:[email protected]

โทร:+86-13758835289

ผลิตอุปกรณ์ที่ดีที่สุดเพื่อสร้างมูลค่าให้กับลูกค้า