- Overview

- Related Products

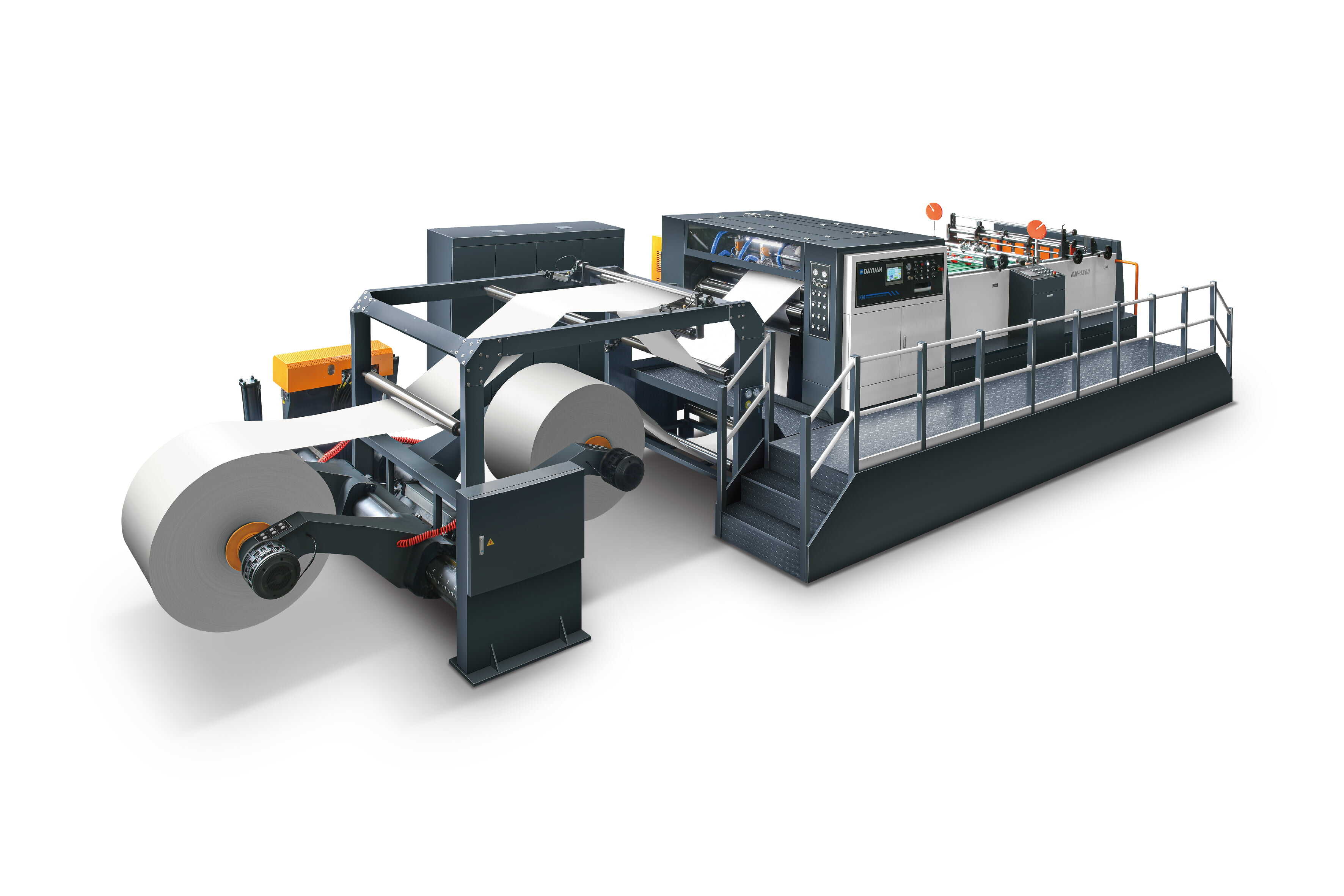

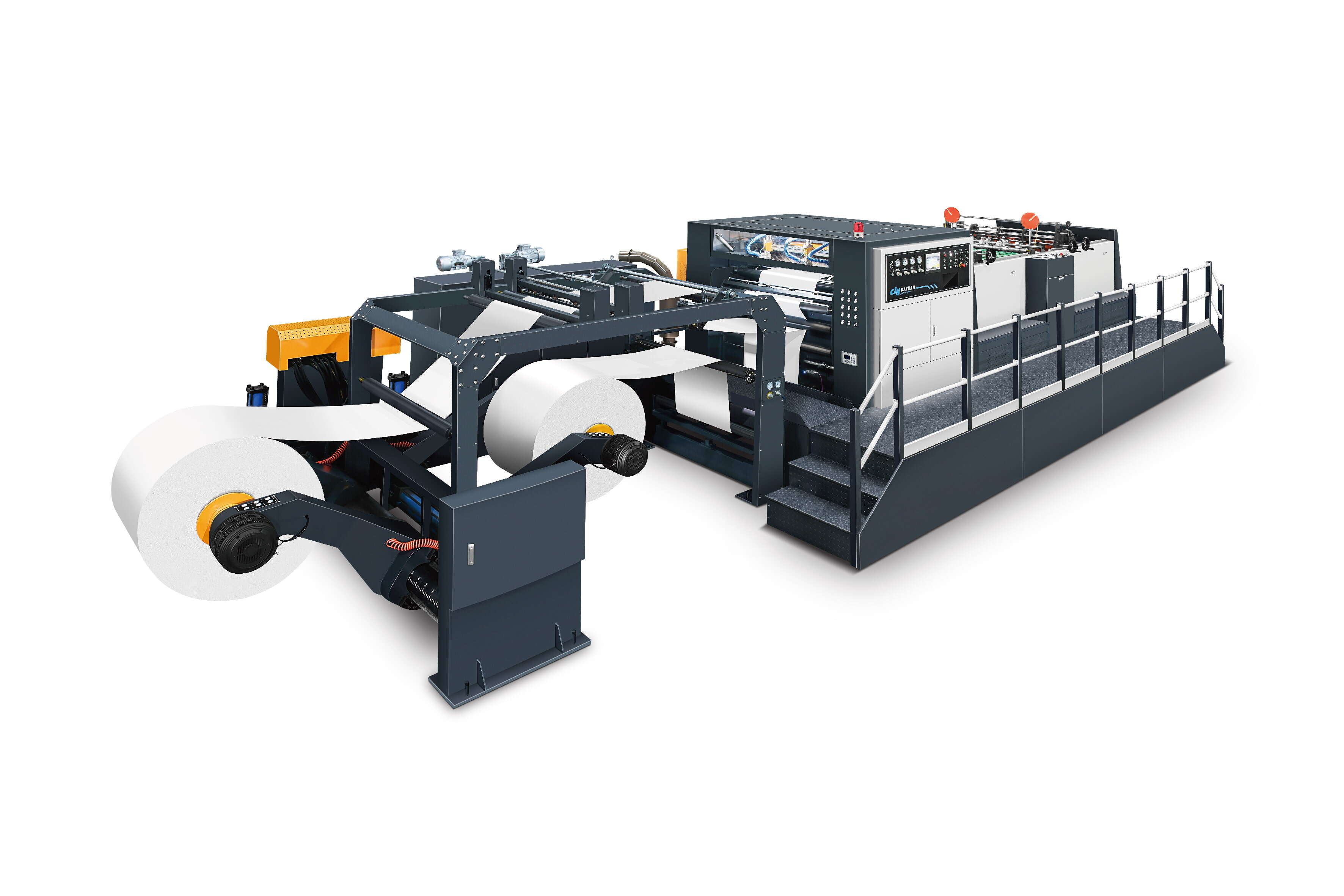

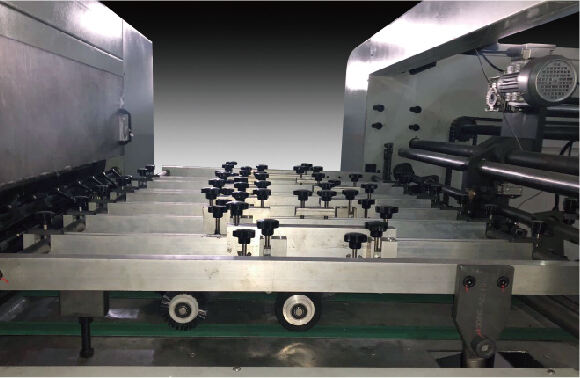

This machine has two operation functions: manual paper feeding and automatic feeder paper feeding. When the corrugated paper is flat, the automatic feeder paper feeding can be adopted to improve efficiency; if the corrugated paper is uneven, manual paper feeding can be used. Controlled by a computer, this machine runs stably and ensures safe production.

|

|

|

| Feeder unit | Servo Motor Conveying Device |

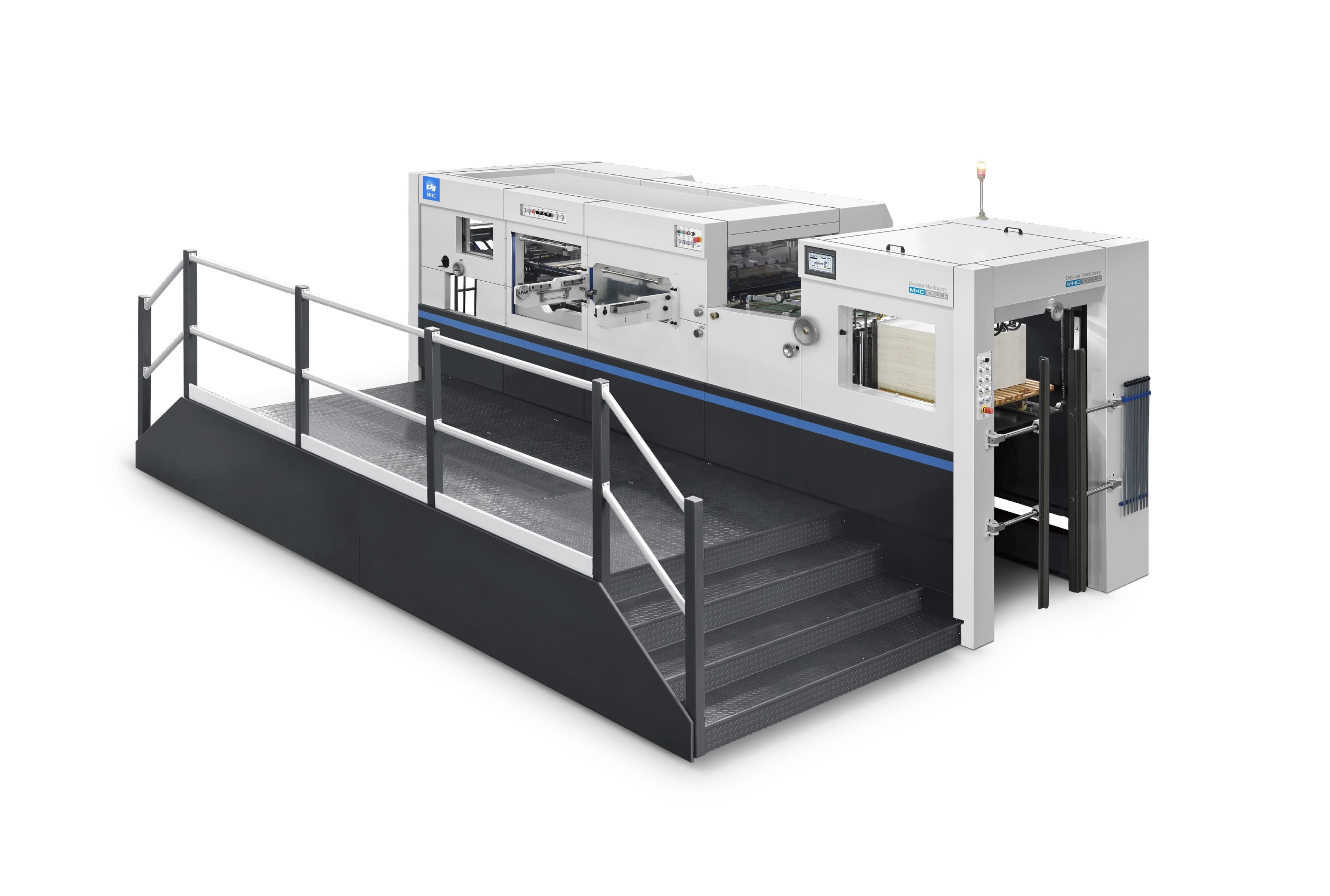

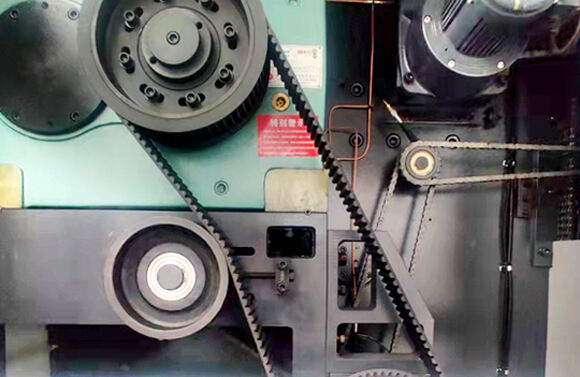

TIMING BELT DRIVEN DEVICETaiwan high precision intermittent segmentation ensure high positional precision for long time usage. ● MHC1100/1300/1350/1500 series intermittent mechanism synchronous belt drive |

|

|

|

|

Waste removal section (three - frame) It adopts a three-frame waste removal mechanism. The intermediate waste removal plate is installed using a rapid center - line positioning method, enabling operators to install the waste removal plate quickly and improving plate - changing efficiency. |

High - stack, rolling - curtain non - stop auxiliary paper - collecting unit Main collecting device and Auto non-stop collecting device switch automati-cally without any operation, which make the machine more effcient. |

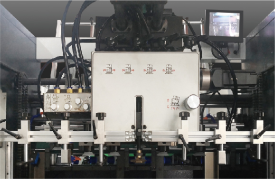

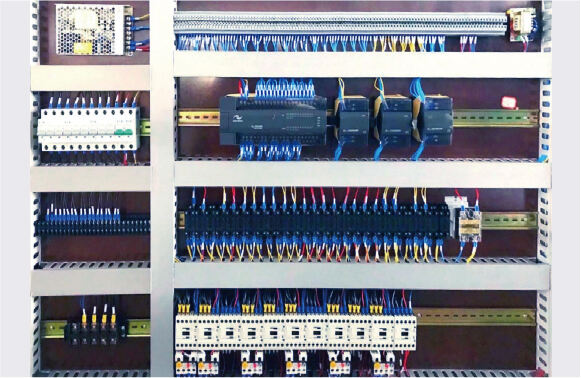

Electrical Unit This machine uses electrical components from German Müller and Japanese Omron. It is easy to operate and convenient to maintain. |

|

||

|

Concentrate lubrication The whole machine is equipped with a centralized automatic oil supply system to ensure that the transmission parts are never short of oil. |

Model |

MHC-1300EC |

MHC-1350EC |

MHC-1500EC |

MHC-1650EC |

Maximum Sheet Size,mm |

1290*940 |

1350*1100 |

1500*1100 |

1650*1200 |

Minimum Sheet Size,mm |

470*450 |

470*450 |

470*450 |

550*500 |

Inner Chase Size,mm |

1310*948 |

1360*1118 |

1510*1118 |

1682*1219 |

Maximum Cutting Size,mm |

1280*920 |

1330*1080 |

1480*1080 |

1620*1180 |

Minimum Gripper Waste,mm |

10~18 |

10~18 |

10~18 |

10~18 |

Minimum Gripper Margin,mm |

9~17 |

9~17 |

9~17 |

9~17 |

Cutting Rule Height,mm |

23.8 |

23.8 |

23.8 |

23.8 |

Stock Range,mm |

Cardboard: ≥ 250g/m², corrugated board: up to 8.5mm, including E, B, C, A and AB flute corrugated paper. |

Cardboard: ≥ 250g/m², corrugated board: up to 8.5mm, including E, B, C, A and AB flute corrugated paper. |

Cardboard: ≥ 300g/m², corrugated board: up to 8.5mm, including E, B, C, A and AB flute corrugated paper. |

Cardboard: ≥ 350g/m², corrugated board: up to 8.5mm, including E, B, C, A and AB flute corrugated paper. |

mm |

≤±0.1 |

≤±0.1 |

≤±0.1 |

≤±0.1 |

Maximum die Cutting Force,T |

400 |

400 |

400 |

400 |

Maximum working Speed,s/h |

5500 |

5500 |

5500 |

4500 |

Net Weight of Machine,T |

19 |

20 |

21 |

23 |

Maximum Pile Height at Delivery(High-stack rolling shutter paper collection),mm |

1600 |

1600 |

1600 |

1600 |

Maximum Pile Height at Delivery(Stacking paper collection with counting ),mm |

1400 |

1400 |

1400 |

1400 |

Main Motor Wattage,KW |

11 |

15 |

15 |

18.5 |

Full Load Wattage,KW |

19 |

24 |

24 |

28 |

Air Requirement |

0.6~0.7MPa,≥0.37m3/min |

0.6~0.7MPa,≥0.37m3/min |

0.6~0.7MPa,≥0.37m3/min |

0.6~0.7MPa,≥0.37m3/min |

FAQ:

Q: What is the delivery time for MHC-EC series?

A: The delivery time is approximately 30 days. The specific time depends on the degree of customization of the project.

Q: Can your machines be used in areas with extreme weather conditions?

A: Generally speaking, they can be used. However, it needs to be analyzed according to the specific environment. You can send an inquiry to consult us.

Q: Are there any color options for the machine?

A: You can customize special color schemes! The color scheme of our equipment is usually as shown in the diagram, and you can customize it according to your preferences.

Q: How to maintain and clean the die - cutting machine?

A: Under the guidance of professionals, regularly clean the machine body and components. Do a good job in lubrication and electrical inspections, calibrate the accuracy, replace vulnerable parts as needed, and maintain the production environment.

Q: Does the machine have safety production measures?

A: Yes, it does. We will train your workers. Meanwhile, safety doors, photoelectric sensors and other facilities are installed on the machine. Warning signs are posted in prominent positions to ensure production is carried out safely and in compliance with regulations. You can also add more safety - production facilities based on what we've provided.

Q: Do you provide installation services? And do you have a warranty period?

A: Certainly. We offer free first - time installation training and provide free spare parts within the one - year warranty period. For services beyond the warranty period, we will charge a reasonable fee.

Are you ready to enhance the efficiency of your production with our printing and packaging solutions? Contact Us today to get a free consultation and quote. Our team of experts is always ready to assist you.

E-mail adress:[email protected]

TEL:+86-13758835289

Manufacture the best equipment to create value for customers.