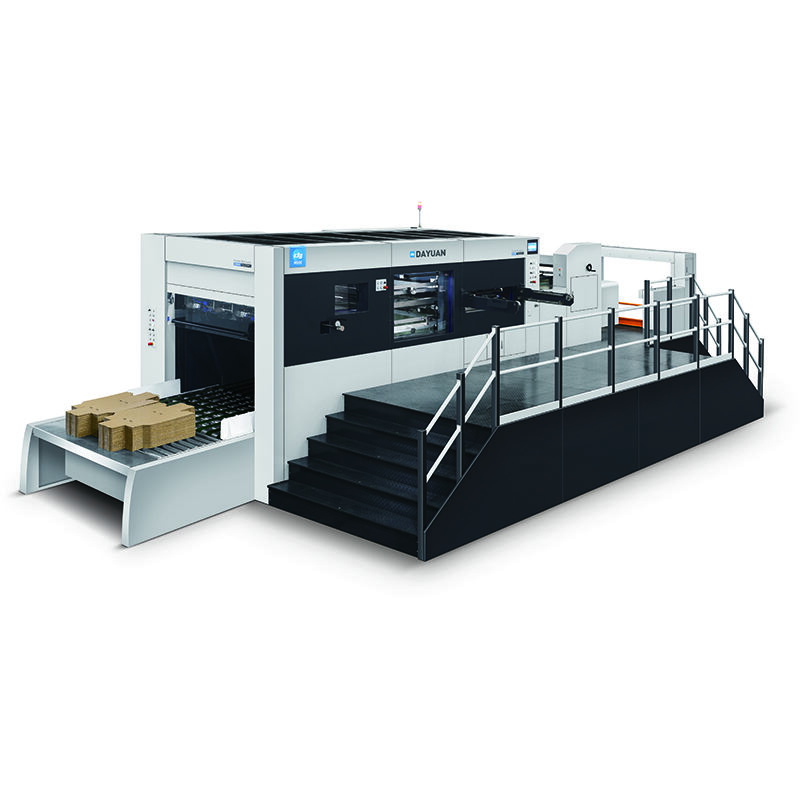

Napredna automatizacija i precizna kontrola

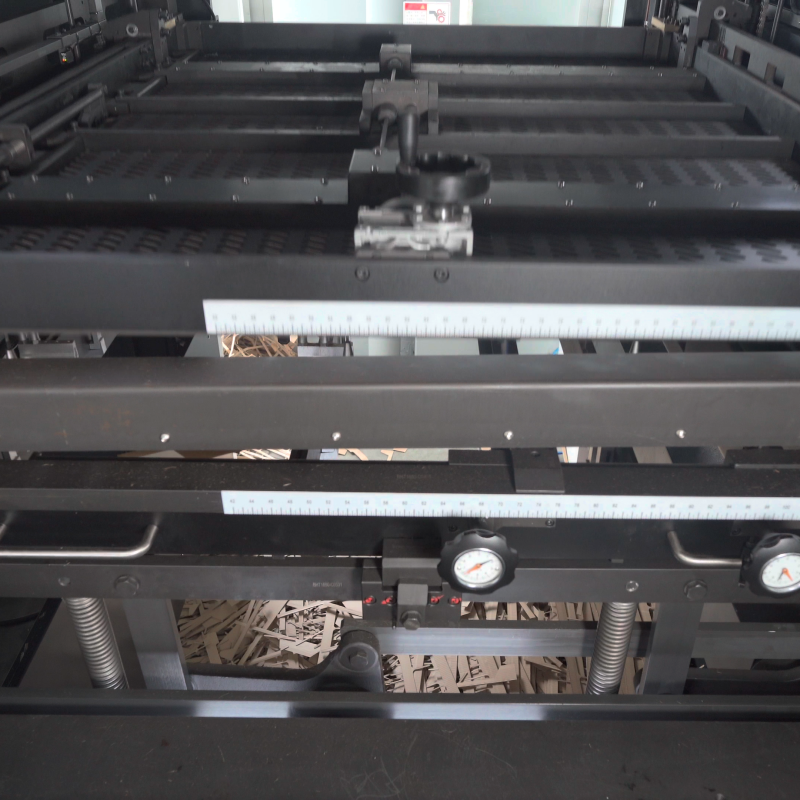

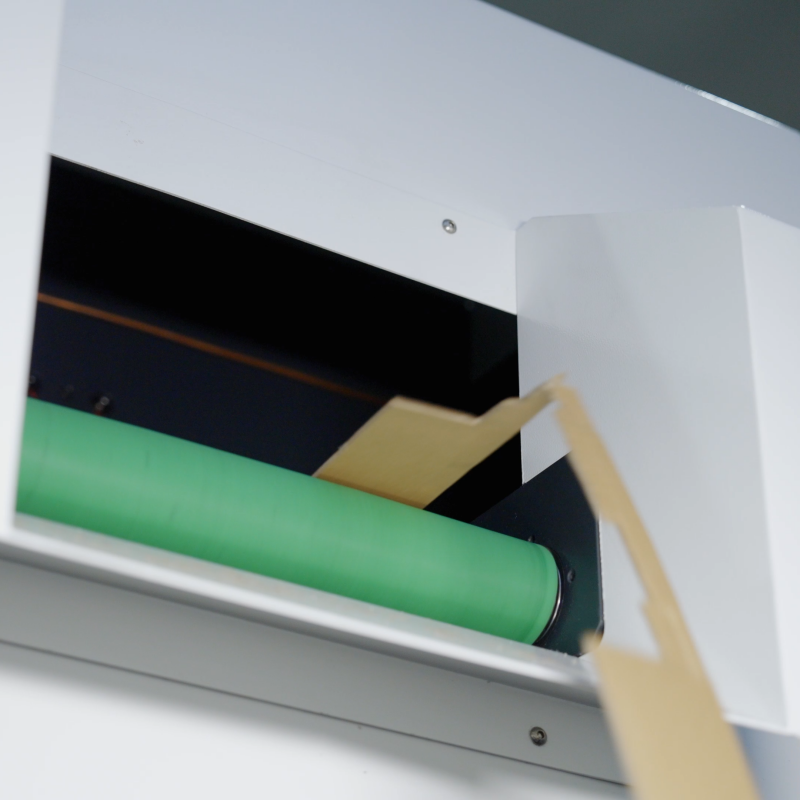

Tvornica za presječnu opremu od kože iznijema u tehnologiji automatskog rada, uz integraciju najnovije računalno upravljane rezne sustave koje nude neverovatnu preciznost i konzistentnost. Svaka rezna stanica je opremljena naprednim servomotorima i sustavima za kontrolu tlaka koji se automatski prilagođavaju različitim debljinama i teksturama kože. Preciznost rezne sile, koja se održava unutar tolerancije od 0,1%, osigurava čiste i točne reze svaki put. Inteligentni mehanizmi povratne informacije sustava neprestano praću i prilagođavaju parametre rezanja, što sprečava uobičajene probleme poput nepotpunih reza ili štete materijalu. Ova napredna automatizacija proširena je i na upravljanje materijalom, uz automatske transportne trake i robote koje smanjuju ljudske pogreške i održavaju tok proizvodnje. Centralni upravljački sustav objekta omogućuje stvarno-vremensko praćenje i prilagođavanje, osiguravajući optimalno djelovanje na svim linijama proizvodnje.