- Overview

- Related Products

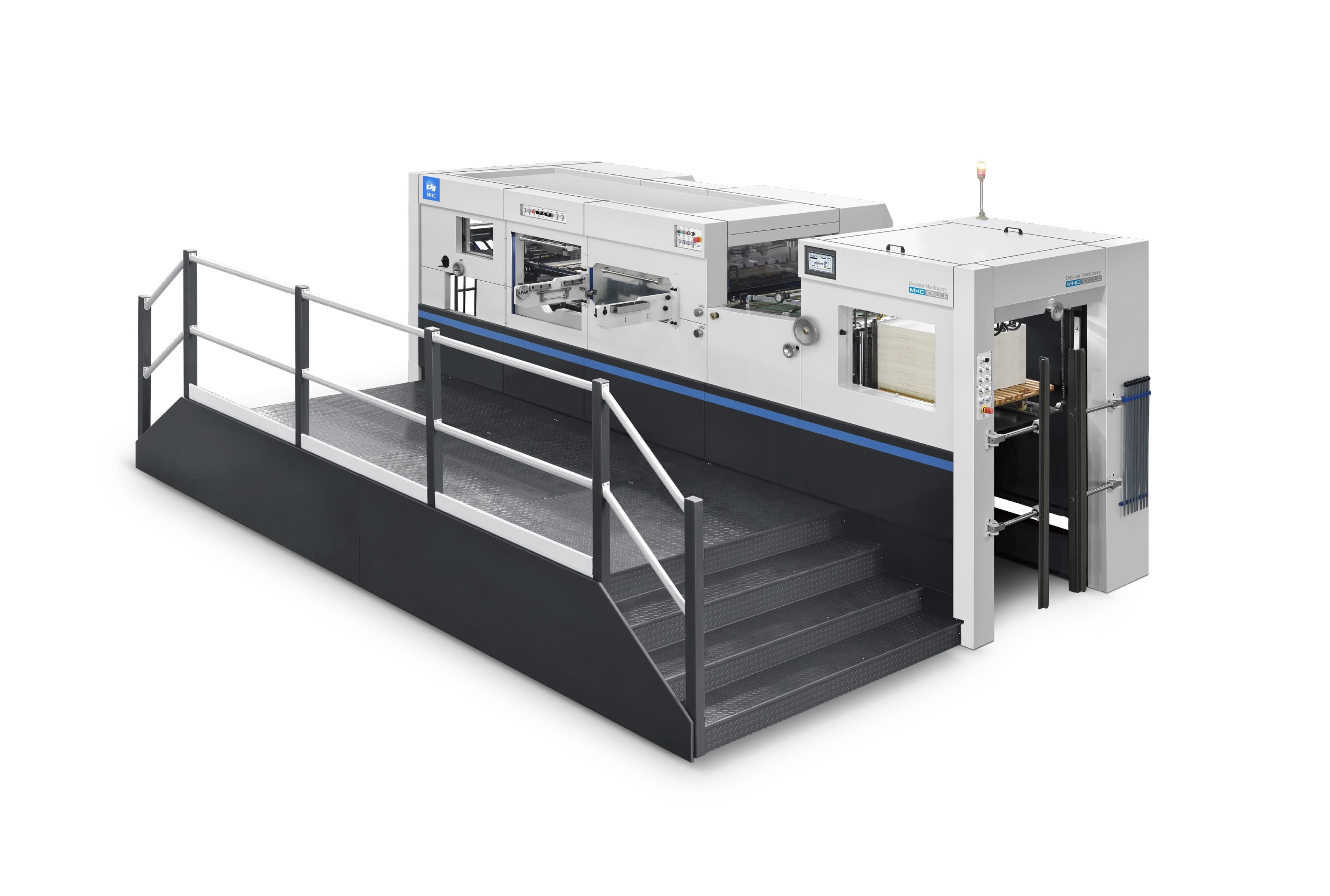

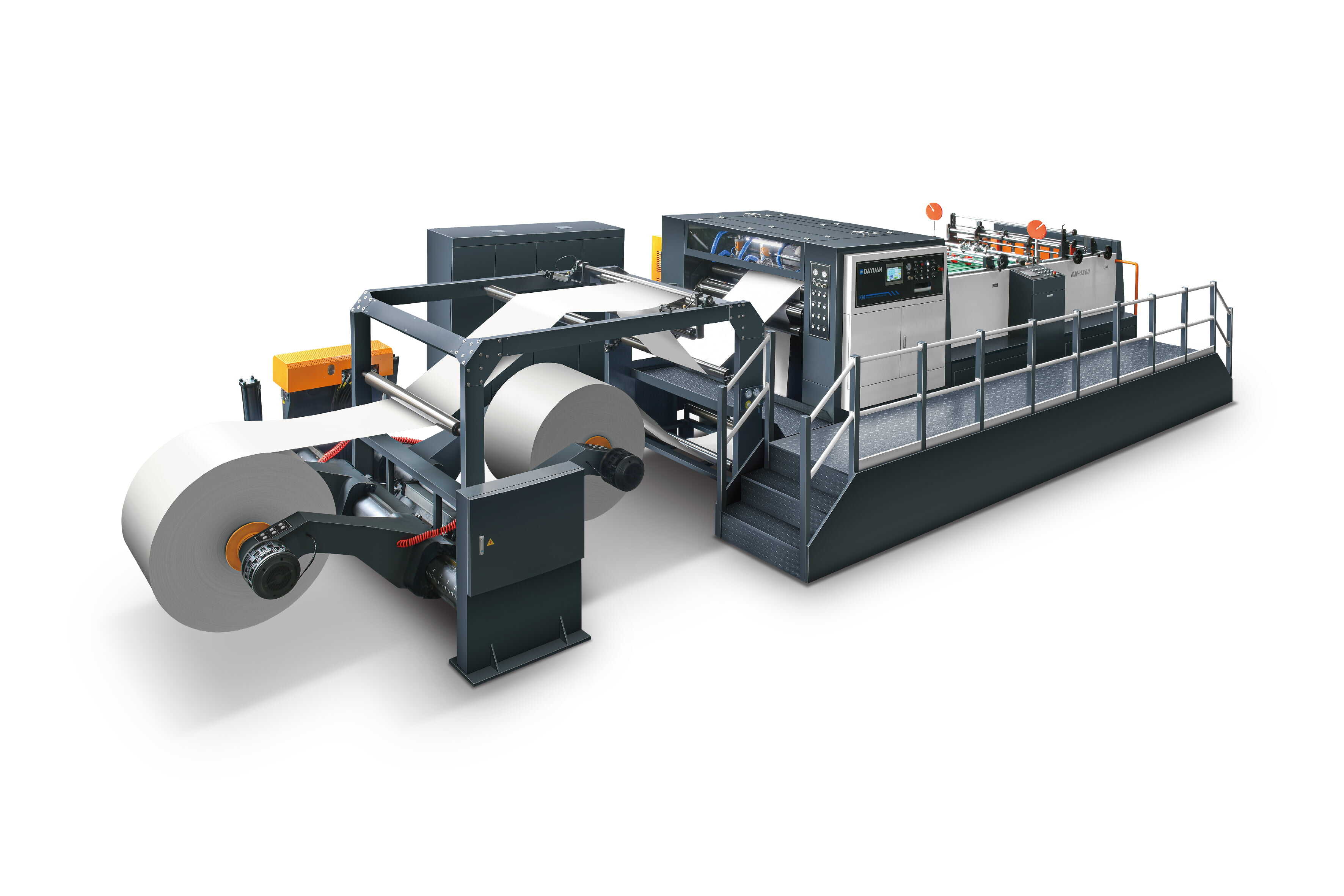

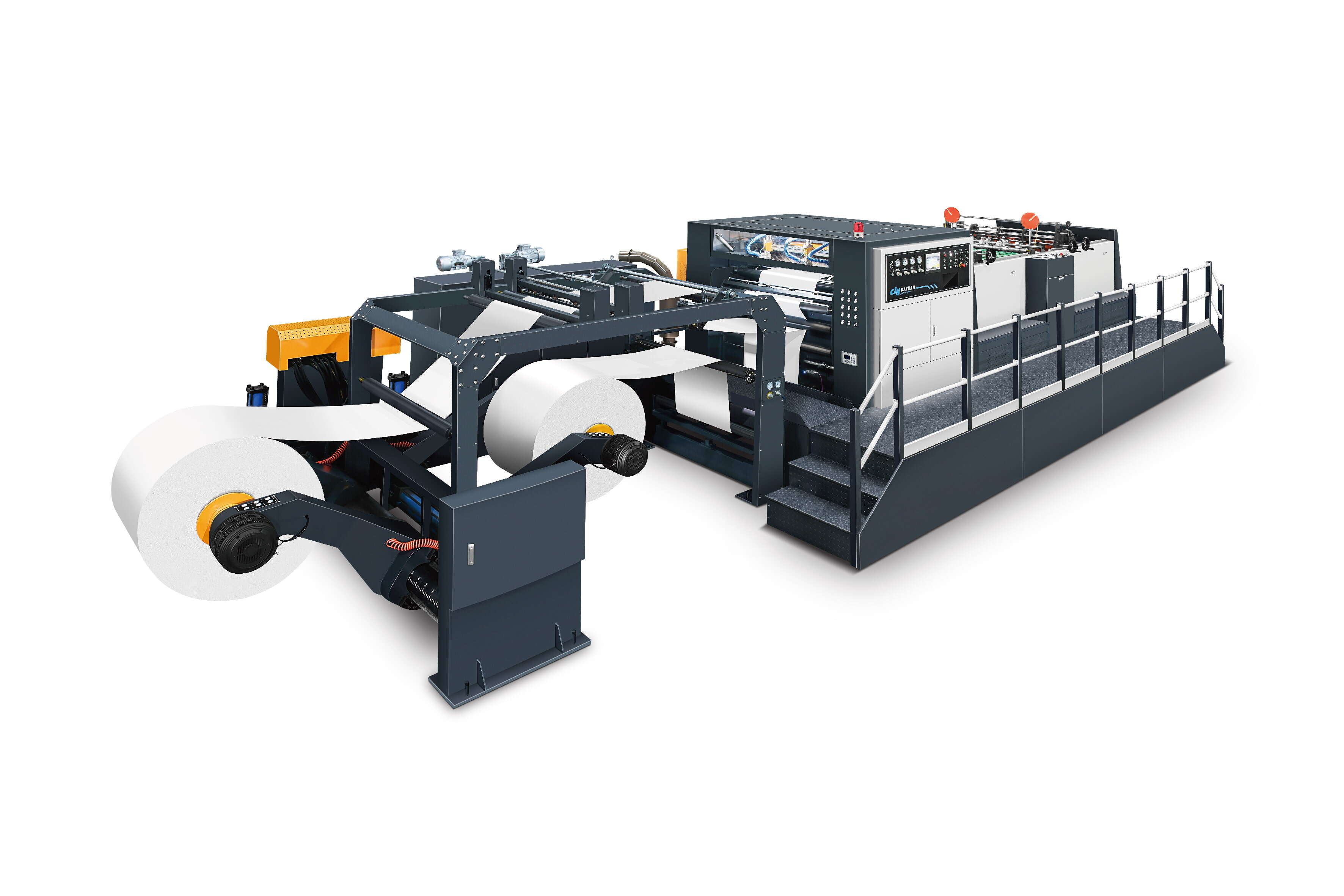

The top-notch BHT-1650FC full-automatic flatbed die-cutting machine with leading edge feeder and waste stripping function of the BHT-FC series adopts an in-line production mode. We will provide reasonable in-line production suggestions according to your production needs, integrating multiple functions, reducing the number of workers, eliminating repetitive operations, and maximizing production capacity. It makes your processes not simplified, halves the number of staff, doubles the efficiency, upgrades the quality, and integrates various processes.

|

|

|

|

1: Push type auto preloader |

2: Multifunctional paper break |

3: Lead Edge Feeder Top gear and precise Lead Edge Feeder design, allowed consistent feeding with various quality corrugated board. New technology polyurethane wheel surface with grid filter and air cushion ensure smooth feeding and accurate alignment even warped board. Fine vacuum suction adjustment through inverter adapts to wide range stock from F flute to double wall corrugate. |

|

|

|

|

4: Sheet Transmission And Alignment Section Selectable left and right side push lays to ensure accurate alignment. Advanced non - stop adjustment of feeding timing, reduce down time. Front gauge non - stop back and forth adjustable to accommodate variation in gripper margin. |

5: Variable Speed Worm Gear Drive Device Worm gear and toggle mechanism allows large motion angle hence minimum number and size of nicks at reasonable max. production speed. |

6: Three Layer Stripping Section The horizontally - fixed waste - removing middle template cooperates with the progressive acceleration motion curve of the waste - removing upper frame's waste - hitting points. The waste - removing structure is simplified, the number of actions is reduced, the instantaneous force of the waste - hitting points is increased, and the waste - removing actions are more concise and effective. When the gripper bar stays in the waste - removing section, it is positioned by relying on a fixed position, making the waste - removing positioning more accurate. A central positioning system is adopted, which enables quick plate - alignment and convenient adjustment. The front waste - removing device can completely remove the waste at the paper - gripping edge, and the conveyor belt sends the waste at the paper - gripping edge out of the machine. |

|

|

|

7: Paper counting & collecting section The non - stop rolling curtain paper collecting and the automatic lifting bracket paper collecting table are used alternately, enabling counted stacking and, at the same time, being conveyed outside the machine by a belt (can be connected to an automatic paper - breaking machine). Electronic counter. The adjustable spring chain tensioned buffer idler wheel greatly reduces the inertia impact of the gripper bar's turning and can maintain the balanced tension of the chain. |

8: Non - stop rolling curtain paper collecting section (standard configuration) Main collecting device and Auto - non - stop collecting device switch automatically without any operation, which make the machine more efficient. |

Model |

BHT-1500FC |

BHT-1650FC |

BHT-1900FC |

BHT-2100FC |

Maximum Sheet Size,mm |

1500×1100 |

1650×1200 |

1900×1400 |

2100×1600 |

Minimum Sheet Size,mm |

480×480 |

650×500 |

650×500 |

750×650 |

Inner Chase Size,mm |

1600×1145 |

1670×1230 |

1920×1430 |

2120×1630 |

Maximum Cutting Size,mm |

1500×1100 |

1630×1180 |

1880×1380 |

2080×1580 |

Minimum Gripper Waste,mm |

10-18 |

10-18 |

10-18 |

10-18 |

Minimum Gripper Margin,mm |

9-17 |

9-17 |

9-17 |

9-17 |

CuttingRuleHeight,mm |

23.8 |

23.8 |

23.8 |

23.8 |

Stock Range,mm |

≤9mm,E、B、C、A,AB corrugated board: up to9mm,including E, B, C, A and AB flute corrugated paper. |

≤9mm,E、B、C、A,AB corrugated board: up to9mm,including E, B, C, A and AB flute corrugated paper. |

≤9mm,E、B、C、A,AB corrugated board: up to9mm,including E, B, C, A and AB flute corrugated paper. |

≤9mm,E、B、C、A,AB corrugated board: up to9mm,including E, B, C, A and AB flute corrugated paper. |

mm |

≤±0.1 |

≤±0.1 |

≤±0.1 |

≤±0.1 |

Mobile Lower Platen Adjusting Range,mm |

±1.5 |

±1.5 |

±1.5 |

±1.5 |

Maximum die Cutting Force,T |

400 |

400 |

450 |

450 |

Maximum working Speed,s/h |

6000 |

6000 |

5000 |

4000 |

Net Weight of Machine,T |

31 |

40 |

46 |

51 |

Maximum Pile Height at Delivery(High-stack rolling shutter paper collection),mm |

1500mm |

1500mm |

1500mm |

1500mm |

Main Motor Wattage,KW |

18.5 |

18.5 |

18.5 |

22 |

Full Load Wattage,KW |

38 |

38 |

40 |

47 |

Air Requirement |

0.6~0.7MPa,≥1m3/min |

0.6~0.7MPa,≥1m3/min |

0.6~0.7MPa,≥1m3/min |

0.6~0.7MPa,≥1m3/min |

Model |

BHT-1500FC |

BHT-1650FC |

BHT-1900FC |

BHT-2100FC |

Maximum Sheet Size,mm |

1520×1120 |

1650×1200 |

1900×1400 |

2100×1600 |

Minimum Sheet Size,mm |

480×480 |

650×450 |

650×450 |

650×450 |

Corrugated board. Up to,mm |

1-9 |

1-9 |

1-9 |

1-9 |

MaximumBatch height,mm |

1800 |

1800 |

1800 |

1800 |

MaximumPile weight,kg |

900 |

1000 |

1200 |

1400 |

Net Weight of Machine,kg |

3500 |

4000 |

4500 |

5000 |

Model |

BHT-1500FC |

BHT-1650FC |

BHT-1900FC |

BHT-2100FC |

Sheet Size,mm |

Max.1520mm,Min.550mm |

Max.1650mm,Min.650mm |

Max.1900mm,Min.650mm |

Max.2100mm,Min.650mm |

Min. Batch dimension in machine,mm |

200 |

200 |

200 |

200 |

Max. Batch thickness,mm |

300 |

300 |

300 |

300 |

Min. Batch thickness,mm |

20 |

20 |

20 |

20 |

Batch passage height from the floor,mm |

900(adjustable) |

900(adjustable) |

900(adjustable) |

900(adjustable) |

Net Weight of Machine,kg |

3500 |

4000 |

4500 |

5000 |

Q: What is the delivery time for BHT-FC series linked?

A: The delivery time is approximately 50 days. The specific time depends on the degree of customization of the project.

Q: Can your machines be used in areas with extreme weather conditions?

A: Generally speaking, they can be used. However, it needs to be analyzed according to the specific environment. You can send an inquiry to consult us.

Q: Are there any color options for the machine?

A: You can customize special color schemes! The color scheme of our equipment is usually as shown in the diagram, and you can customize it according to your preferences.

Q: How to maintain and clean the die - cutting machine?

A: Under the guidance of professionals, regularly clean the machine body and components. Do a good job in lubrication and electrical inspections, calibrate the accuracy, replace vulnerable parts as needed, and maintain the production environment.

Q: Does the machine have safety production measures?

A: Yes, it does. We will train your workers. Meanwhile, safety doors, photoelectric sensors and other facilities are installed on the machine. Warning signs are posted in prominent positions to ensure production is carried out safely and in compliance with regulations. You can also add more safety - production facilities based on what we've provided.

Q: Do you provide installation services? And do you have a warranty period?

A: Certainly. We offer free first - time installation training and provide free spare parts within the one - year warranty period. For services beyond the warranty period, we will charge a reasonable fee.

Are you ready to enhance the efficiency of your production with our printing and packaging solutions? Contact Us today to get a free consultation and quote. Our team of experts is always ready to assist you.

E-mail adress:[email protected]

TEL:+86-13758835289

Manufacture the best equipment to create value for customers.