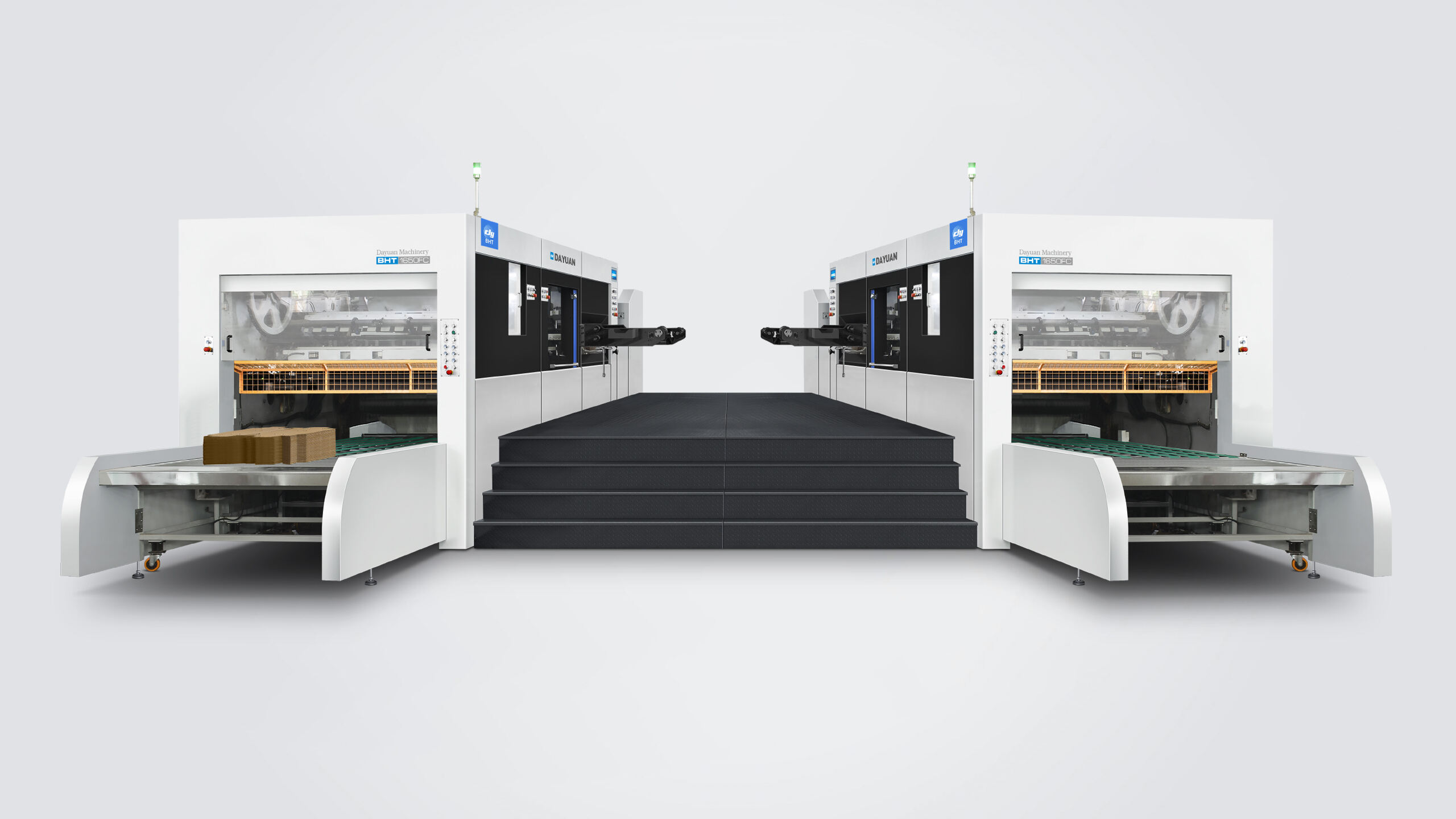

BHT-1500FC/1650FC/1900FC/2100FC

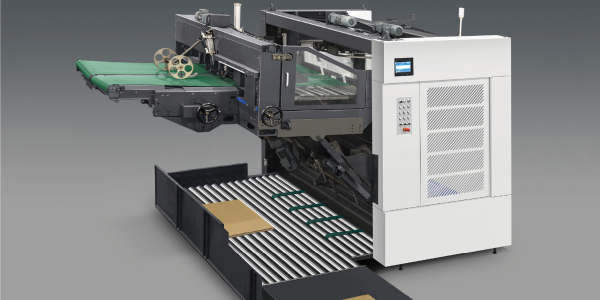

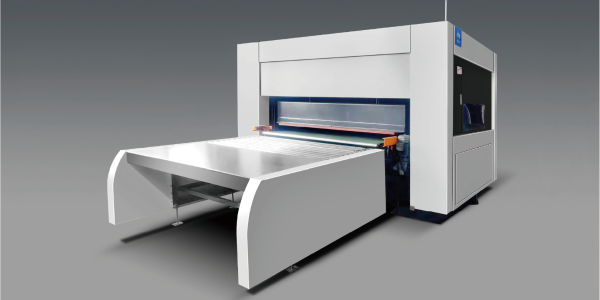

Automatic Die Cutting Machine Linkage Production Line

- Flexible customization for exact product requirements

- Automated feeding system and multi-functional paper breaker

- Covering all ranges from 1520×1100mm to 2100×1600mm

- Overview

- Technical Parameters

- Related Products

Product Description

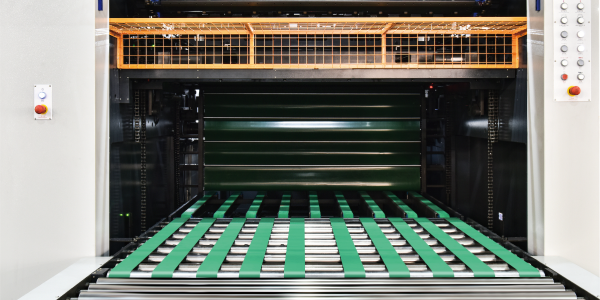

Dayuan Automatic Die Cutting Machine Linkage Production Line is designed for large-format die-cutting operations. Building upon standalone machines, this system incorporates automatic feeding devices and multi-functional sheet breaker to revolutionize your workflow. By equipping the feeding section with automated paper handling systems, it eliminates manual paper transportation - significantly reducing labor intensity while boosting feeding efficiency by up to 40%. The output section features intelligent multi-up sheet separation that automatically divides processed products, slashing labor costs for manual sorting and maximizing overall equipment productivity. This integrated solution delivers unparalleled handling capability for corrugated board processing, offering flexible size configurations with maximum sheet size ranging from 1520×1100mm to 2100×1600mm to accommodate diverse production requirements.

|

|

|

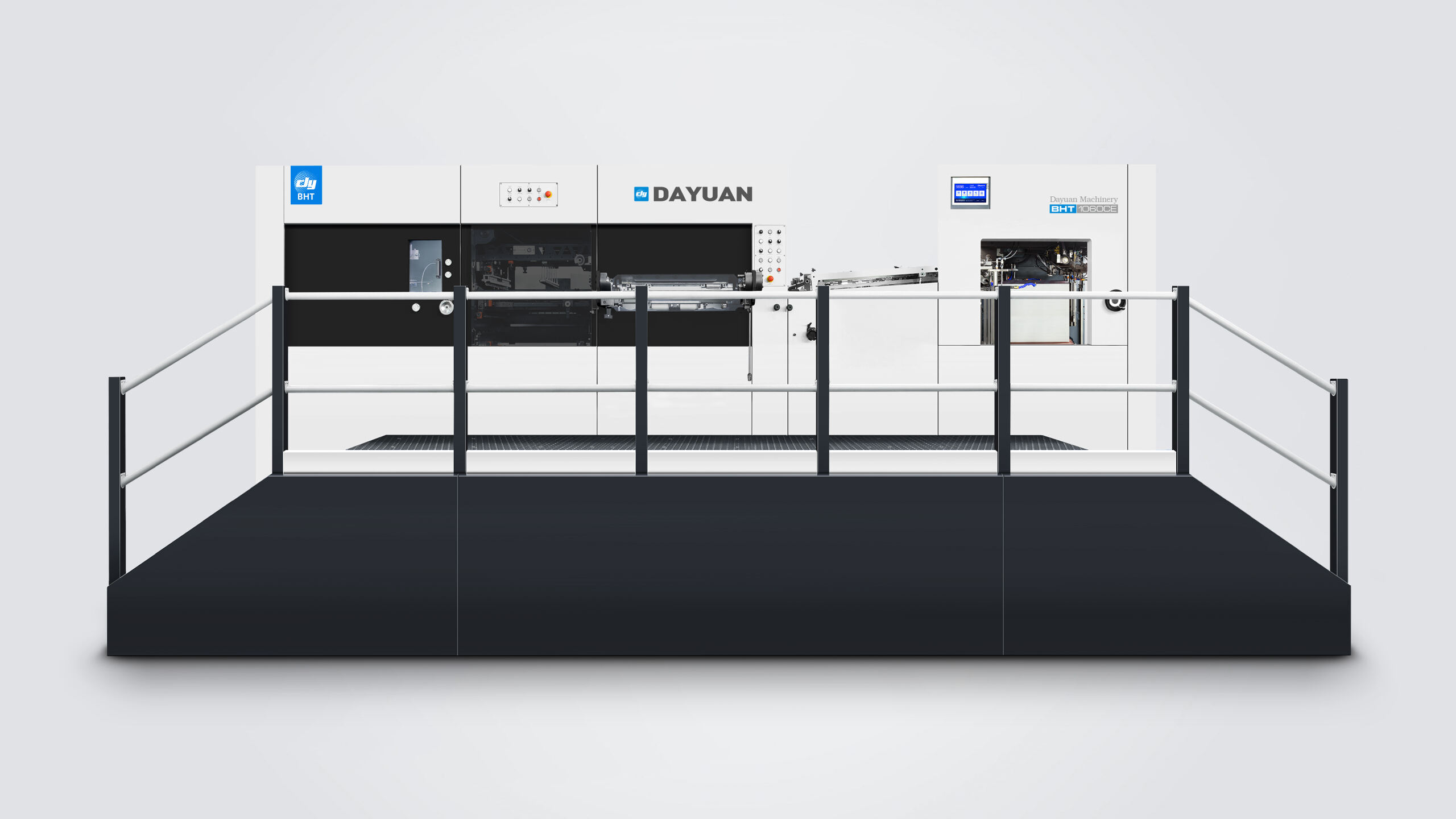

Lead edge feeder |

Down feeder |

Sheet transmission and alignment section |

|

|

|

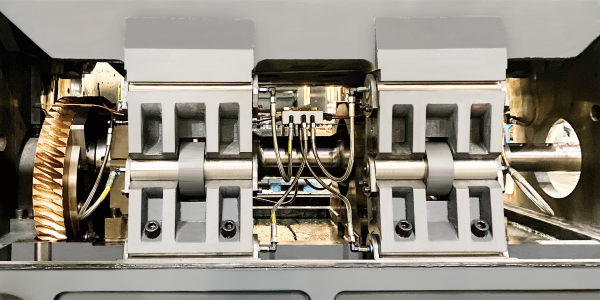

Variable speed worm gear drive device |

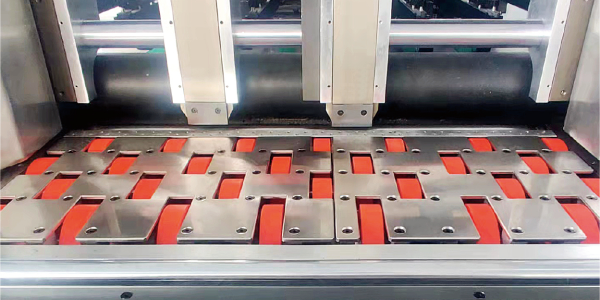

Die cutting unit |

Three layer stripping section |

|

|

|

Gripper margin stripping device |

Non-stop stacking delivery unit(Standard) |

Batch delivery conveying unit(Optional) |

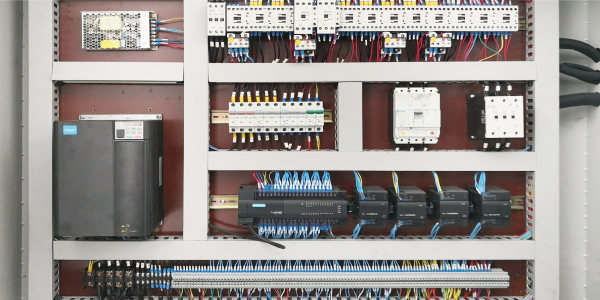

Electrical unit |

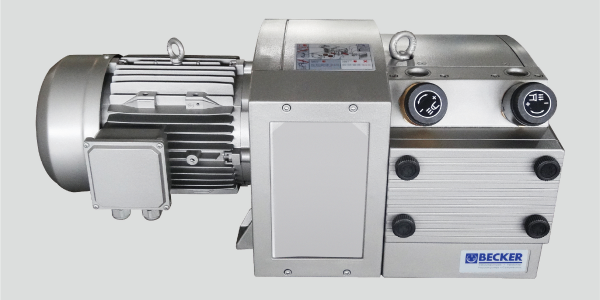

Germany vacuum pump |

Auto lubrication system |

|

|

|

Push type auto preloader |

Multifunctional paper breaker |

Technical Parameters

Die Cutting Machine

|

Model |

BHT-1500FC BHT-1500EFC |

BHT-1650FC BHT-1650EFC |

BHT-1900FC BHT-1900EFC |

BHT-2100FC BHT-2100EFC |

|

Maximum Sheet Size |

1520×1100mm |

1650×1200mm |

1900×1400mm |

2100×1600mm |

|

Minimum Sheet Size |

480×480mm |

650×500mm |

650×500mm |

750×650mm |

|

Maximum Cutting Size |

1500×1100mm |

1630×1180mm |

1880×1380mm |

2080×1580mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

9-17mm |

|

Minimum Width of Cuts |

10-18mm |

10-18mm |

10-18mm |

10-18mm |

|

Cutting Rule Height |

23.8mm |

23.8mm |

23.8mm |

23.8mm |

|

Inner Chase Size |

1600×1145mm |

1670×1230mm |

1920×1430mm |

2120×1630mm |

|

Stock Range |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

|

Die Cutting Accuracy |

≤±0.15mm |

≤±0.2mm |

≤±0.2mm |

≤±0.2mm |

|

Max.Cutting Force |

400T |

400T |

450T |

450T |

|

Max.Working Speed |

6000s/h |

6000s/h |

5000s/h |

4000s/h |

|

Maximum Delivery Pile Height |

1500mm |

1500mm |

1500mm |

1500mm |

|

Main Motor Power |

18.5KW |

18.5KW |

18.5KW |

22KW |

|

Full Load Wattage |

38KW / 36KW |

38KW / 38KW |

40KW / 40KW |

47KW / 47KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

31T / 33T |

40T / 41T |

46T / 47T |

51T / 52T |

|

Machine Dimension (Stacking Delivery) (L×W×H) |

9887×5500×2800mm |

10344×5970×2876mm(FC) |

11853×6560×2972mm(FC) |

14370×7160×2972mm |

|

10187×5970×2876mm(EFC) |

11652×6560×2972mm(EFC) |

|||

|

Machine Dimensions (Batch Delivery Conveying) (L×W×H) |

11400×5500×2800mm |

12049×5970×2876mm(FC) |

13690×6560×2972mm(FC) |

15870×7160×2972mm |

|

11892×5970×2876mm(EFC) |

13489×6560×2972mm(EFC) |

Auto Preloader

|

Model |

BHT-1500FC/EFC |

BHT-1650FC/EFC |

BHT-1900FC/EFC |

BHT-2100FC/EFC |

|

Maximum Sheet Size |

1520×1120mm |

1650×1200mm |

1900×1400mm |

2100×1600mm |

|

Minimum Sheet Size |

480×480mm |

650×450mm |

650×450mm |

650×450mm |

|

Corrugated board. Up to |

1-9mm |

1-9mm |

1-9mm |

1-9mm |

|

Maximum Batch height |

1800mm |

1800mm |

1800mm |

1800mm |

|

Maximum Pile weight |

900kg |

1000kg |

1200kg |

1400kg |

|

Net Weight of Machine |

3500kg |

4000kg |

4500kg |

5000kg |

Multifunctional Paper Breaker

|

Model |

BHT-1500FC/EFC |

BHT-1650FC/EFC |

BHT-1900FC/EFC |

BHT-2100FC/EFC |

|

Sheet Size |

Max.1520mm Min.550mm |

Max.1650mm Min.650mm |

Max.1900mm Min.650mm |

Max.2100mm Min.650mm |

|

Min. Batch dimension in machine |

200mm |

200mm |

200mm |

200mm |

|

Max. Batch thickness |

300mm |

300mm |

300mm |

300mm |

|

Min. Batch thickness |

20mm |

20mm |

20mm |

20mm |

|

Batch passage height from the floor |

900mm(adjustable) |

900mm(adjustable) |

900mm(adjustable) |

900mm(adjustable) |

|

Net Weight of Machine |

3500kg |

4000kg |

4500kg |

5000kg |