- Огляд

- Супутні продукти

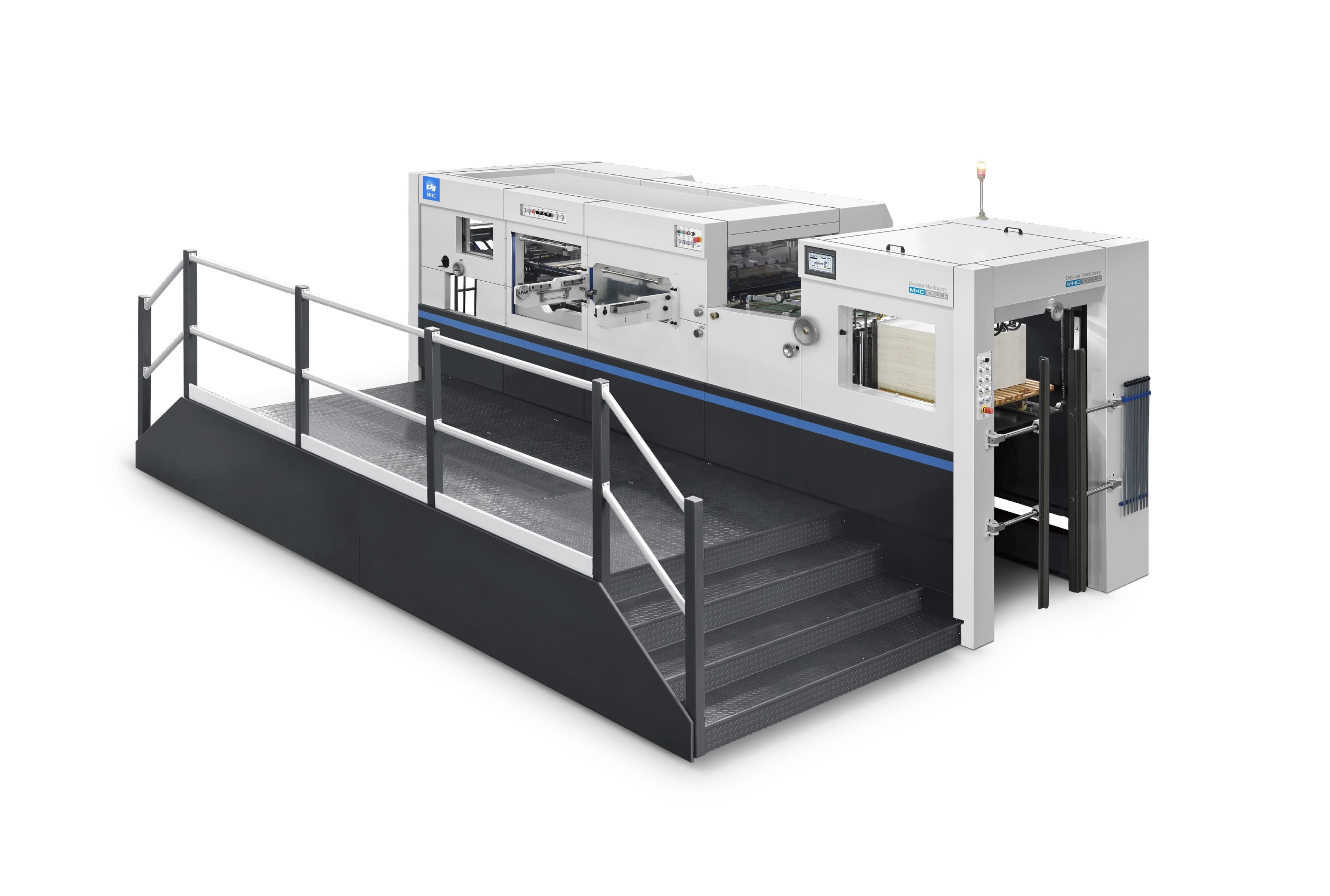

Напівавтоматичний верстат для висікання та біговки серії MHC використовує високоякісні гріпери для паперу. Він підходить для різних типів паперу. Керований комп'ютером, він має просту та зрозумілу експлуатацію. Датчики та засоби безпеки встановлені в кількох частинах корпусу машини для забезпечення нормальної роботи машини та особистої безпеки.

|

|

|

|

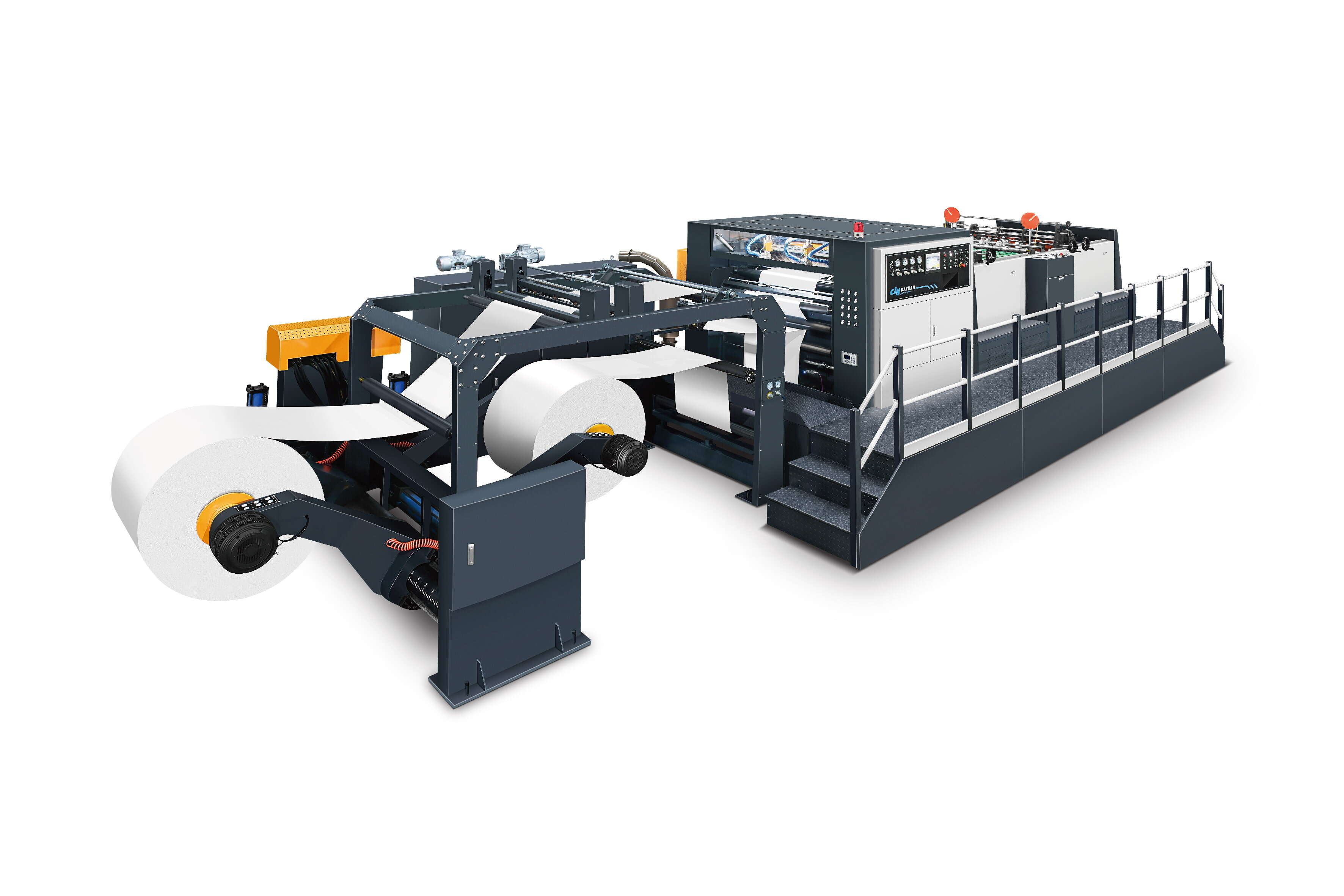

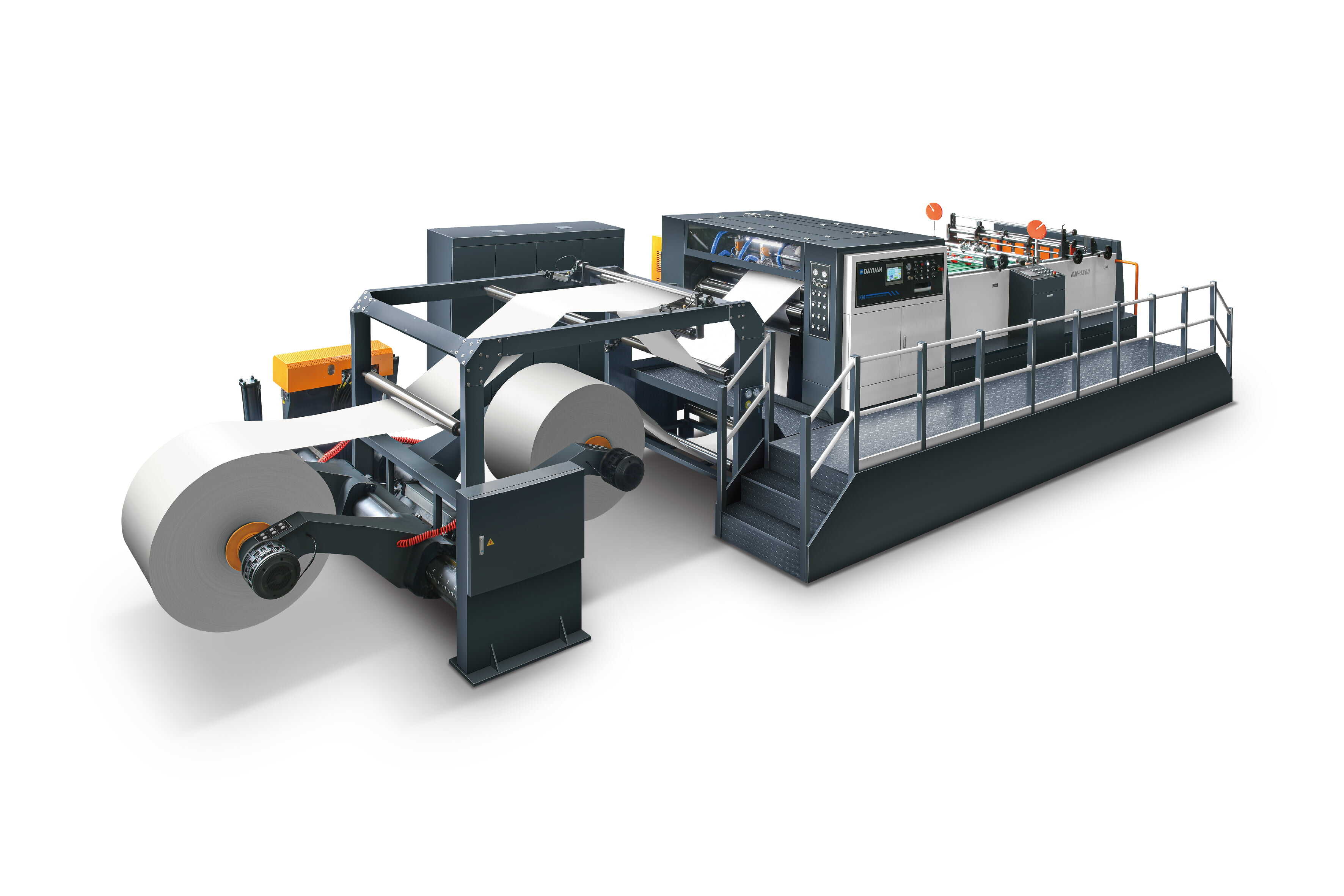

Секція збору паперу з безперервним рулонним завісом Основний пристрій збору та автоматичний пристрій безперервного збору перемикаються автоматично без будь-яких операцій, що робить машину більш ефективною. |

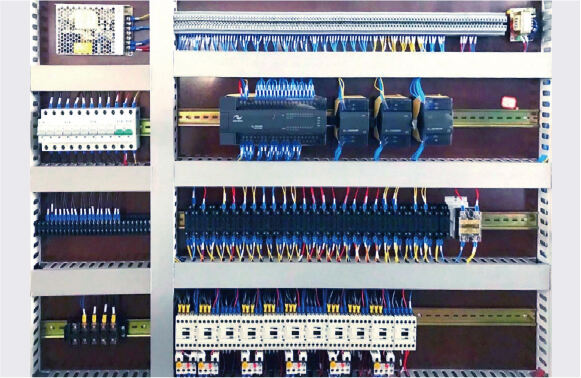

Електричний блок Цей верстат використовує електричні компоненти німецького Müller та японського Omron. Його легко експлуатувати та зручно обслуговувати. |

Концентроване змащення Вся машина обладнана централізованою автоматичною системою постачання олії, щоб забезпечити, що частини трансмісії ніколи не відчувають нестачі олії. |

Модель |

MHC-1100B |

MHC-1300B |

MHC-1350B |

MHC-1500B |

MHC-1650B |

MHC-1900B |

Максимальний розмір аркуша, мм |

1100×790 |

1290×940 |

1350×1100 |

1500×1100 |

1650×1200 |

1900×1400 |

Мінімальний розмір аркуша, мм |

400×350 |

470×450 |

470×450 |

470×450 |

550×500 |

650×550 |

Внутрішній розмір шасі, мм |

1120×786 |

1310×948 |

1360×1118 |

1510×1118 |

1682×1219 |

1912×1419 |

Максимальний розмір різання, мм |

1070×770 |

1280×920 |

1330×1080 |

1480×1080 |

1620×1180 |

1870×1380 |

Мінімальна ширина подвійних різів, мм |

--- |

--- |

--- |

--- |

--- |

--- |

Мінімальний запас захоплювача, мм |

9-17 |

9-17 |

9-17 |

9-17 |

9-17 |

9-17 |

Висота різального правила, мм |

23.8 |

23.8 |

23.8 |

23.8 |

23.8 |

23.8 |

Діапазон матеріалу, мм |

гофрокартон: до 7мм, включаючи гофри E, B, C, A та AB. |

гофрокартон: до 8.5мм, включаючи гофри E, B, C, A та AB. |

гофрокартон: до 8.5мм, включаючи гофри E, B, C, A та AB. |

гофрокартон: до 8.5мм, включаючи гофри E, B, C, A та AB. |

гофрокартон: до 8.5мм, включаючи гофри E, B, C, A та AB. |

гофрокартон: до 8.5мм, включаючи гофри E, B, C, A та AB. |

Точність висікання, мм |

≤±0.1 |

≤±0.1 |

≤±0.1 |

≤±0.1 |

≤±0.1 |

≤±0.1 |

Максимальна сила різання, Т |

300 |

400 |

400 |

400 |

400 |

300 |

Максимальна робоча швидкість, с/год |

7500 |

5500 |

5500 |

5500 |

4500 |

3500 |

Чиста вага машини, Т |

13 |

15 |

16 |

17 |

20 |

22 |

Максимальна висота стопи на подавачі - нормальний режим, мм |

1600 |

1600 |

1600 |

1600 |

1600 |

1600 |

Максимальна висота стопи на вивантаженні, мм |

1400 |

1400 |

1400 |

1400 |

1400 |

1400 |

Потужність при повному навантаженні, кВт |

14 |

14 |

18 |

18 |

22 |

22 |

Вимоги до повітря |

0.6~0.7MPa, ≥0.37m3/min |

0.6~0.7MPa, ≥0.37m3/min |

0.6~0.7MPa, ≥0.37m3/min |

0.6~0.7MPa, ≥0.37m3/min |

0.6~0.7MPa, ≥0.37m3/min |

0.6~0.7MPa, ≥0.37m3/min |

Питання та відповіді

П: Який термін доставки для серії MHC-B?

В: Термін доставки приблизно 30 днів. Конкретний час залежить від ступеня налаштування проекту.

Q: Чи можуть ваші машини використовуватися в умовах екстремальної погоди?

A: Загалом, їх можна використовувати. Однак це потрібно аналізувати відповідно до конкретного середовища. Ви можете надіслати запит, щоб проконсультуватися з нами.

Q: Чи є варіанти кольорів для машини?

A: Ви можете налаштувати спеціальні кольорові схеми! Кольорова схема нашого обладнання зазвичай показана на діаграмі, і ви можете налаштувати її відповідно до ваших уподобань.

Q: Як підтримувати та чистити машину для різання?

A: Під керівництвом професіоналів регулярно очищайте корпус машини та компоненти. Добре виконуйте змащення та електричні перевірки, калібруйте точність, замінюйте вразливі частини за потреби та підтримуйте виробниче середовище.

Q: Чи має машина заходи безпеки під час виробництва?

A: Так, це так. Ми навчимо ваших працівників. Тим часом, на машині встановлені безпечні двері, фотоелектричні датчики та інші засоби. Попереджувальні знаки розміщені в помітних місцях, щоб забезпечити безпечне виконання виробництва та відповідність нормам. Ви також можете додати більше засобів безпеки - виробництва на основі того, що ми надали.

Q: Чи надаєте ви послуги з установки? І чи є у вас гарантійний термін?

A: Звичайно. Ми пропонуємо безкоштовне навчання з установки вперше та надаємо безкоштовні запасні частини протягом одного року гарантійного терміну. За послуги після закінчення гарантійного терміну ми стягуватимемо розумну плату.

Ви готові підвищити ефективність вашого виробництва з нашими рішеннями для друку та упаковки?Зв'яжіться з намисьогодні, щоб отримати безкоштовну консультацію та пропозицію. Наша команда експертів завжди готова допомогти вам.

Електронна адреса: dayuan@dayuanmachinery.com

ТЕЛ: +86-13758835289

Виготовляйте найкраще обладнання для створення цінності для клієнтів.