BHT-3S1060TTRSCE (TRIOPRESS Automatische Hochgeschwindigkeits-Doppelseitige Heißfolienprägedruckmaschine mit Trennung und Ausstanzung)

- Übersicht

- Verwandte Produkte

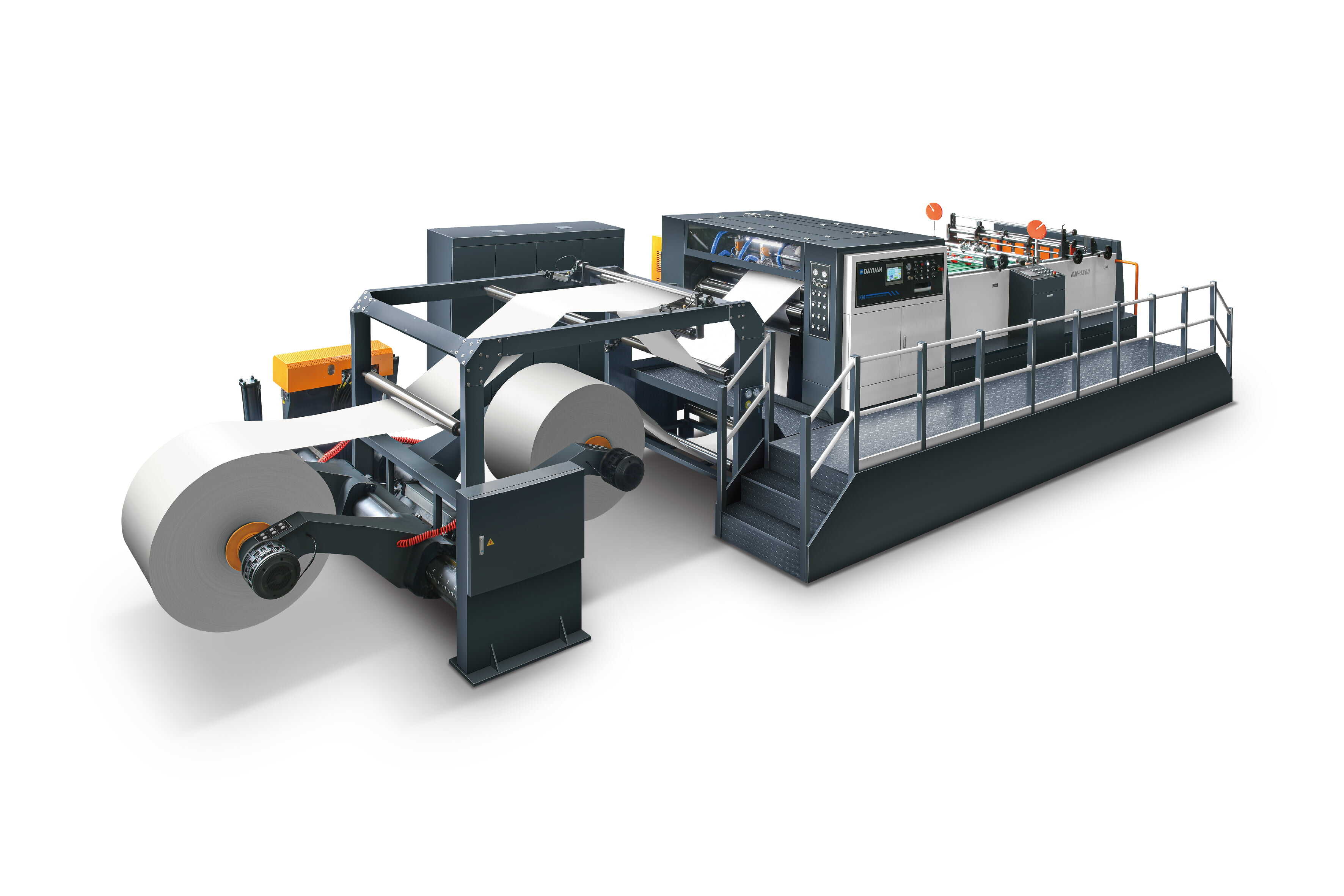

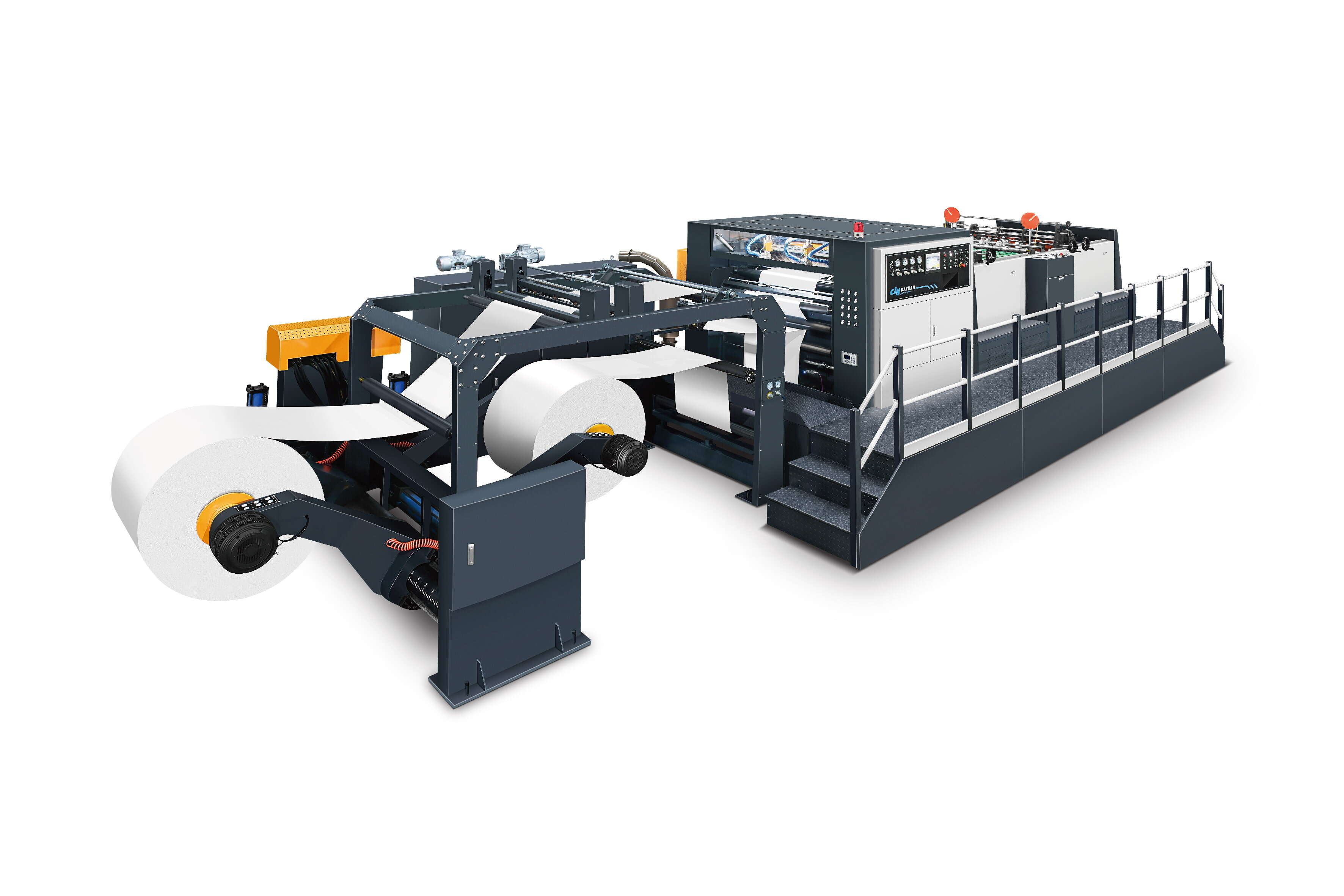

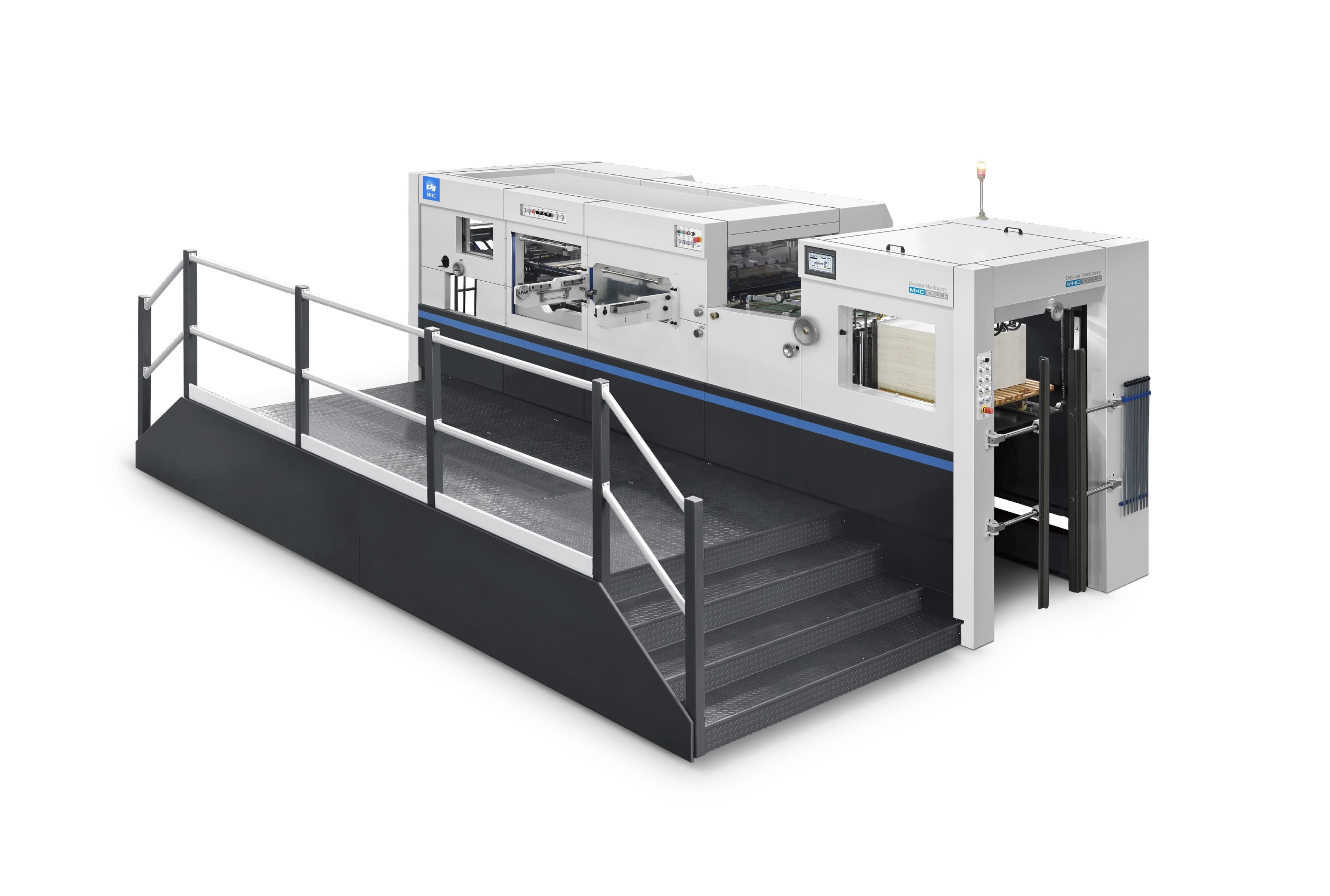

Die erstklassige BHT-3S1060TTRSCE TRIOPRESS Automatische Hochgeschwindigkeits-Doppel-Heißpräge-Stanzmaschinemit Entfernen und Ausstanzung. Diese dreistationige Schneidemaschine integriert die Funktionen der Doppel-Heißpräge, Heißpressung und vollständiger Abfallentfernung. Sie bietet präzise Lösungen für verschiedene Papierbearbeitungsaufgaben, helfen Ihnen dabei, hochwertiges PapierProdukte. Der bahnbrechende Dreistations-Betriebsmodus vereinfacht Prozesse, reduziert die Anzahl der Mitarbeiter um die Hälfte, verdoppelt die Effizienz und verbessert die Qualität erheblich. Zweifellos ist es eine ausgezeichnete Wahl für die Herstellung hochwertiger Papierprodukte.

|

|

|

|

1: Zuführer Basierend auf einer fortgeschrittenen technischen Plattform, füttert sie präzise und konsistent einen breiten Bereich von Vorräten, von 90g/m² dünnem Papier bis zu 1000g/m² Karton sowie Mikroflutwellpappe. |

2: Doppellagendetektor Ultraschall-Doppeltblatt-Detektor ohne Berührung des Papiers, daher kratzfrei, zuverlässig und schnell einstellbar. |

3: Greiferleiste Greiferleisten aus modernster Technologie, die dank des einzigartigen Designs des großen Bewegungswinkels des exzentrischen Schneckengetriebes extrem reibungslos laufen. |

|

|

|

|

4: Servogesteuertes Positionierungsgerät für die Greiferleiste Die hintere Positionierung der Greiferleiste verwendet ein Servosteuerungssystem. Die präzise Genauigkeit jeder Greiferleiste kann über die Tasten auf dem PLC-Touchscreen eingestellt werden, was die Präzision der Greiferleiste sicherstellt, die dauerhaft eine Genauigkeit von ±0,075 mm erreicht (patentiertes Produkt). |

5: Mikroeinstellgerät für die Wabenplatte Maximaler Stempeldruck bis zu 600 Tonnen, was es ermöglicht, bessere 3D- und präzise Effekte auf großen Druckmaterialien wie Weinkisten und Zigarettenkisten zu erzielen.<br> |

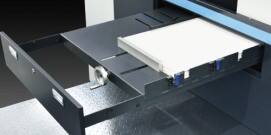

6: Mikroeinstellgerät für die Schneidplatte 15 mm gehärtete Schneidplatte oder 4+1 mm Sandwichplatte auf einer 15 mm präzisen synthetischen Trägerplatte mit +/-0,9 mm Mikroeinstellung für schnelle Einrichtung und einfache Vorbereitung. |

|

|

|

|

7: Feinabstimmungsvorrichtung für die Plattenrahmen Adoptiere das Mittelachsen-System und das Schnellverschlussgerät, um die Rüstzeit zu sparen. |

8: Fortgeschrittenes Werkzeugfixierungssystem Ein fortschrittliches schnelles Werkzeugsatzsystem sorgt für eine schnelle Auftragswechsel und damit für eine hohe Produktivität sowohl beim Abschlagen als auch beim Ausformen. |

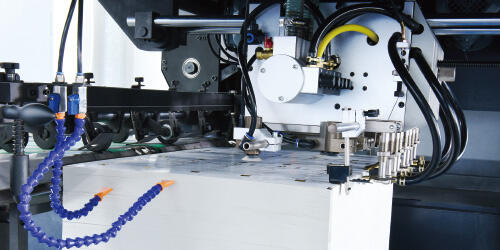

9: Kühl- und Schmiermechanismus des Hauptmotors Die Schmierung des Hauptmotors während des langfristigen Hochgeschwindigkeitsbetriebs wird sichergestellt, und die normale Temperatur des Schmieröls des Hauptmotors wird durch das automatische öl-pumpende zirkulierende Kühlsystem aufrechterhalten. |

|

|

|

|

10: Vollflächige Abgabe Option für vollflächige Abgabe, um durch Auswahl des Endabgabestils eine einfache Produktionsplanung zu gewährleisten. |

11: Automatische Blatttrennvorrichtung Automatische Blatttrennvorrichtung mit elektronischem Positionsensor am Ausformstation. |

12: Ununterbrochenes Probenentnahme Die Probenfunktion kann verwendet werden, um ein Probenblatt im Flug durch einen Knopfdruck zu entfernen, einfach zu bedienen. |

|

|

|

13: Deutscher Vakuumpumpe Deutsche Becker ölfreie Blaspumpe und Vakuumpumpe. |

14: Konzentrierte Schmierung Effizientes Konzentratschmiersystem ermöglicht es der Maschine, über längere Zeit mit hoher Geschwindigkeit zu laufen, indem es die Hauptantriebsketten, wichtige Nocken und Lager schmiert. |

Modell |

BHT-3S1060TTRSCE |

Maximale Blattgröße,mm |

1060×760 |

Minimale Blattgröße,mm |

400×350 |

Größe des inneren Chase,mm |

1080×770 |

Maximale Schnittgröße,mm |

1060×745 |

Maximale Stempelgröße,mm |

1060×740 |

MaximumHeizungGröße,mm |

1060×740 |

Minimale Breite der Doppelschnitte,mm |

5 |

Minimaler Greiferrand,mm |

9-17 |

SchneidenRegelHacht,mm |

23.8 |

Lagersortiment,mm |

80~2000g/m²,0,1~2mm,≤4mm Papier: von 80 bis 2000g/m2, 0,1~2mm, Wellpappe: bis zu 4mm |

Stempelgenauigkeit,mm |

≤±0.075 |

HolografischPPositionierungsEmpfindlichkeitsprüfungPGenauigkeit (opt.),mm |

≤±0.075 |

Heizgenauigkeit,mm |

≤±0.075 |

Stanzgenauigkeit,mm |

≤±0.075 |

Maximale Stanzkraft,t |

600t +600t+600t |

Maximale Arbeitsgeschwindigkeit,s/h |

6200 |

Nettogewicht der Maschine,t |

64 |

Maximale Stapelhöhe am Einleger - Normalbetrieb,mm |

1800 |

Maximale Stapelhöhe am Einleger - Non-stop-Betrieb,mm |

1520 |

Maximale Stapelhöhe bei Lieferung,mm |

1580 |

rking SMax.gold Folien Durchmesser |

Ф250mmLängsrichtung,Ф200mmDurchschnitts |

Elektrisch beheiztes System |

20Heizzonen,40~180℃Verstellbar |

Folienbreite,mm |

20~1060 |

Presse 1 Folienvorschubwellen |

3Längsrichtung+2Durchschnitts(opt) |

Presse 2 Folienvorschubwellen |

3Längsrichtung+2Durchschnitts(opt) |

Press 3 |

Elektrisch beheiztes System |

Leistung bei Volllast,kW |

157 |

Luftbedarf |

0.6~0,7 MPa,≥1m3/min |

1. Heißfolienprägung + Heißfolienprägung + Profilieren (Tiefprofilieren)

2. Heißfolienprägung + Heißfolienprägung + Schneiden + Abfallentfernung + Sortierung

3. Heißfolienprägung + Profilieren (Tiefprofilieren) + Schneiden + Abfallentfernung + Sortierung

4. Profilieren (Tiefprofilieren) + Profilieren (Tiefprofilieren) + Schneiden + Abfallentfernung + Sortierung

(FAQ):

Q: Was ist die Lieferzeit für BHT-3S1060TTRSCE?

A: Die Lieferzeit beträgt ungefähr 80 Tage. Die genaue Zeit hängt vom Grad der Anpassung des Projekts ab.

Q: Können Ihre Maschinen in Gebieten mit extremen Wetterbedingungen eingesetzt werden?

A: Allgemein gesagt, können sie verwendet werden. Es muss jedoch je nach spezifischer Umgebung analysiert werden. Sie können eine Anfrage senden, um uns zu konsultieren.

Q: Gibt es Farboptionen für die Maschine?

A: Sie können spezielle Farbschemata anpassen! Das Farbschema unserer Geräte ist normalerweise wie im Diagramm dargestellt, und Sie können es nach Ihren Wünschen anpassen.

Q: Wie pflegt und reinigt man die Stanzmaschine?

A: Unter der Anleitung von Fachleuten regelmäßig den Maschinenkörper und die Komponenten reinigen. Eine gute Schmierung und elektrische Inspektionen durchführen, die Genauigkeit kalibrieren, anfällige Teile nach Bedarf ersetzen und die Produktionsumgebung pflegen.

Q: Hat die Maschine Sicherheitsproduktionsmaßnahmen?

A: Ja, das tut es. Wir werden Ihre Mitarbeiter schulen. In der Zwischenzeit werden Sicherheitstüren, fotoelektrische Sensoren und andere Einrichtungen an der Maschine installiert. Warnschilder sind an prominenten Stellen angebracht, um sicherzustellen, dass die Produktion sicher und gemäß den Vorschriften durchgeführt wird. Sie können auch weitere Sicherheits- Produktionsanlagen basierend auf dem, was wir bereitgestellt haben, hinzufügen.

Q: Bieten Sie Installationsdienste an? Und haben Sie eine Garantiezeit?

A: Sicherlich. Wir bieten kostenlose Schulungen zur Erstinstallation an und stellen innerhalb der einjährigen Garantiezeit kostenlose Ersatzteile zur Verfügung. Für Dienstleistungen über die Garantiezeit hinaus erheben wir eine angemessene Gebühr.

Sind Sie bereit, die Effizienz Ihrer Produktion mit unseren Druck- und Verpackungslösungen zu steigern?Kontaktieren Sie unsheute, um eine kostenlose Beratung und ein Angebot zu erhalten. Unser Team von Experten steht Ihnen immer zur Verfügung.

E-Mail-Adresse: [email protected]

TEL: +86-13758835289

Stellen Sie die beste Ausrüstung her, um Wert für die Kunden zu schaffen.